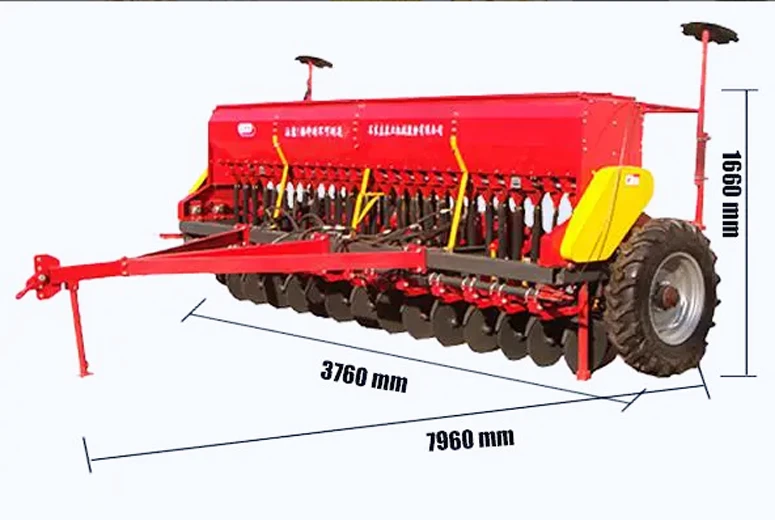

CONFIGURATION PARAMETERS

| Model | 2BFY-24 | 2BFY-28 | 2BFY-36 |

| Matching power (Hp) | 70-120 | 70-120 | 80-180 |

| Sowing width(mm) | 3600 | 4200 | 5400 |

| Number of rows | 24 | 28 | 36 |

Basic row spacing(mm) |

150 | 150 | 150 |

| Sowing depth(mm) | 40-80 | 40-80 | 40-80 |

| Working efficiency(hectare/h) | 2.16-3.6 | 2.52-4.2 | 3.42-5.4 |

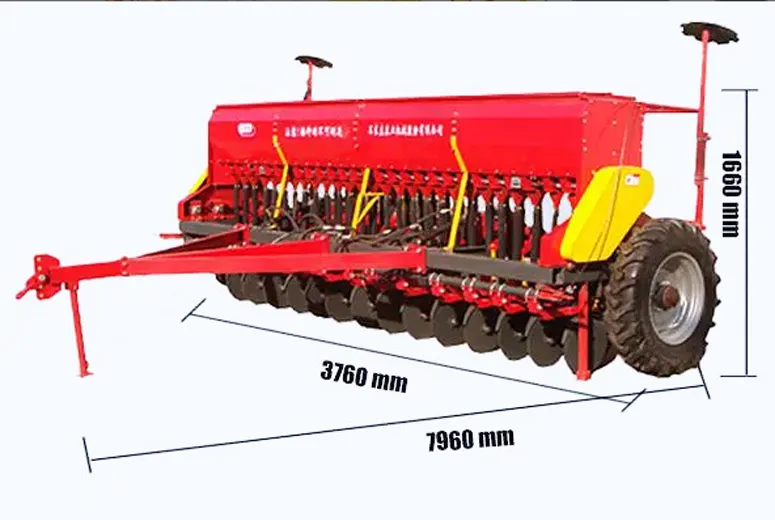

PRODUCT DETAILS PICTURES

PRODUCT ADVANTAGES

The 2BFY Traction Series Grain Fertilizer Seeder stands out as a pinnacle of innovation in agricultural equipment, designed to revolutionize the seeding and fertilizing process for modern farmers. Engineered with precision and efficiency in mind, this seeder combines advanced technology with robust functionality to meet the diverse needs of agricultural operations.

One of the key advantages of the 2BFY Traction Series Seeder is its integrated design, which seamlessly combines seeding and fertilizing functions into a single operation. This integration not only saves valuable time but also optimizes the use of resources by ensuring the precise placement of both seeds and fertilizer in the soil. Farmers can achieve higher efficiency in planting and fertilizing, leading to improved crop yields and reduced operational costs.

Another standout feature of this seeder is its versatility across various crops and terrains. Whether planting grains, cereals, or legumes, the 2BFY Seeder adapts effortlessly, thanks to adjustable settings that cater to different seed sizes and spacing requirements. Its robust traction system ensures stability and uniformity even on uneven or challenging ground, providing consistent seeding depth and coverage across the entire field.

Durability and ease of maintenance are further advantages offered by the 2BFY Traction Series. Constructed from high-quality materials and components, it withstands the rigors of continuous use in demanding agricultural environments. Routine maintenance is straightforward, minimizing downtime and maximizing productivity during critical planting seasons.

Moreover, the 2BFY Traction Series embraces user-friendly features that enhance operator comfort and control. From ergonomic design elements to intuitive controls, every aspect is crafted with the operator in mind, promoting efficiency and reducing fatigue during extended work periods.

In conclusion, the 2BFY Traction Series Grain Fertilizer Seeder represents a pinnacle of agricultural technology, combining precision, efficiency, and versatility to empower farmers with the tools they need to achieve optimal crop yields and sustainable agricultural practices. For modern farming operations looking to enhance productivity and profitability, this seeder sets a new standard in performance and reliability.

2BFY Traction Seeder: Precision in Synchronized Grain & Fertilizer Sowing

The 2BFY Traction Seeder redefines planting efficiency, mastering synchronized grain and fertilizer sowing to boost yields. Crafted by a leading agricultural machinery manufacturer, this agricultural seeder machine blends accuracy and speed, standing out among seeder farm equipment for its ability to harmonize seeds and nutrients in one pass.

At its heart is a synchronized dual-channel system that eliminates separate sowing and fertilizing passes. Unlike traditional seeder farm equipment, it places seeds and fertilizer together: fertilizer sits 2-3cm below and beside each seed, creating an ideal nutrient zone for germination. Farmers adjust seed spacing (5-20cm) and fertilizer dosage (10-50kg/acre) via a simple panel, tailoring settings to crops—critical for a wheat seeder machine needing dense spacing for wheat versus wider gaps for corn.

Engineered for adaptability, the seeder’s spring-loaded discs maintain consistent depth (2-5cm) across uneven terrain. They slice through clay without resistance and avoid over-penetration in sandy soils, outperforming rigid agricultural seeder machine models that struggle with variable ground.

Efficiency transforms workflows: pulled by a standard tractor, it covers 10-15 acres/day—triple the rate of manual sowing or single-row tools. Its 3-meter working width cuts passes, saving fuel and labor, while large hoppers (200kg seeds, 300kg fertilizer) reduce refill stops during tight planting windows.

Durability ensures longevity: a high-strength steel frame resists jolts, and wear-resistant plastic liners prevent clogs from damp soil or fertilizer. Protective shields guard moving parts from debris, a testament to the agricultural machinery manufacturer’s focus on reliability.

For wheat farmers, this wheat seeder machine excels: even spacing (10-12cm) promotes uniform growth, while synchronized fertilizer fuels early development, boosting yields. As agricultural seeder machine options go, it delivers value: 20% less fertilizer waste, faster planting, and consistent results.

More than a tool, it’s a partnership of seeds, nutrients, and machinery—by a agricultural machinery manufacturer that knows precision sowing grows success. For farmers chasing better harvests, this seeder delivers: synchronized precision that counts, season after season.

From Seeds to Fertilizer: Integrated Systems in 2BFY Grain Fertilizer Agricultural Seeder Machine

The 2BFY Grain Fertilizer agricultural seeder machine revolutionizes planting through its integrated systems, seamlessly connecting seed placement and fertilizer distribution. Designed by a leading agricultural machinery manufacturer, it stands apart from conventional seeder farm equipment by unifying two critical tasks into one efficient process, redefining precision for grain growers.

At the core of its innovation is a dual-chamber integrated system that eliminates the need for separate sowing and fertilizing passes. The machine’s synchronized mechanism ensures seeds and fertilizer are deposited in perfect harmony: seeds go into the soil at 2-5cm depth, with fertilizer placed 2-3cm below and beside them—creating an optimal nutrient zone that accelerates germination. This integration cuts operational time by 50% compared to traditional seeder farm equipment, which requires two passes over the same field.

As a versatile wheat seeder machine, it offers adjustable settings to suit diverse crops. Farmers can tweak seed spacing (5-20cm) and fertilizer dosage (10-50kg/acre) via a user-friendly interface, ensuring wheat gets dense spacing for maximum yield while corn or rice receive customized placement. The system’s sensors monitor flow rates in real time, alerting operators to blockages or uneven distribution—preventing wasted seeds or fertilizer.

Engineered for adaptability, the integrated system works with spring-loaded discs that maintain consistent depth across uneven terrain, from clay-heavy fields to sandy soils. This stability ensures uniform germination, a key advantage over rigid agricultural seeder machine models that struggle with variable ground.

Durability is built into every component: the steel frame resists wear from daily use, while corrosion-resistant liners protect the fertilizer chamber from chemical damage. The agricultural machinery manufacturer’s focus on integration extends to ease of maintenance, with quick-access panels for cleaning and part replacement—minimizing downtime during busy planting seasons.

For farmers, this integration translates to tangible benefits: reduced fuel costs, lower labor demands, and precise resource use that cuts waste by up to 20%. As a wheat seeder machine and multi-crop solution, it proves that unifying seed and fertilizer systems isn’t just efficient—it’s essential for maximizing yields in modern agriculture.

In essence, the 2BFY’s integrated systems embody the agricultural machinery manufacturer’s vision: to turn separate farming tasks into a cohesive, high-performance process. For growers seeking to bridge the gap between seeds and fertilizer with unmatched efficiency, this agricultural seeder machine delivers a seamless solution that grows better results, season after season.

News