Enhancing Efficiency in Speed Transmission Systems for Optimal Performance

Understanding Speed Transmission The Key to Efficient Power Delivery

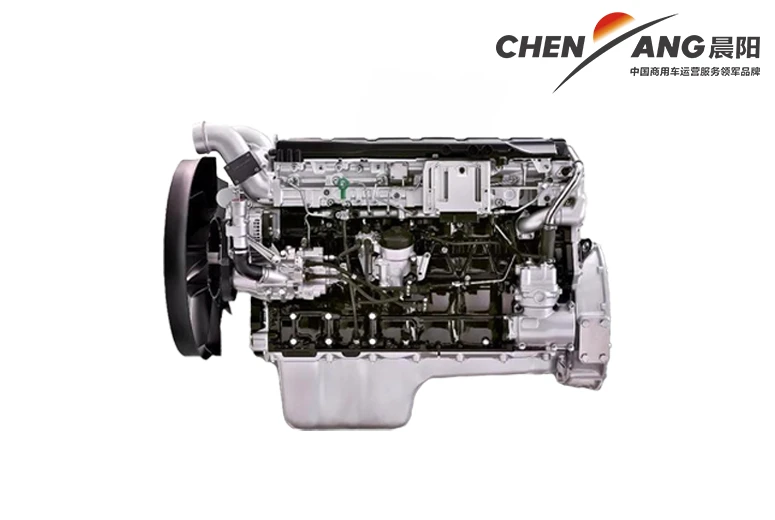

In the fast-paced world of engineering and technology, speed transmission refers to the mechanism through which power and motion are transferred from one component to another. This concept is fundamental in various applications, including automotive engineering, aircraft systems, and industrial machinery. The efficiency and reliability of these transmission systems significantly impact performance, making it essential to comprehend their inner workings and innovations.

Speed transmission encompasses several systems, with the most common examples being gears, belts, chains, and hydraulic systems. Each of these systems operates on similar principles but varies in design, application, and efficiency. The primary goal is to match the output speed and torque to the requirements of the driven system.

1. Gear Systems

Gears are one of the most prevalent methods of speed transmission. They consist of toothed wheels that interlock to transfer motion and force. The speed of rotation can be increased or decreased through a gear ratio – the ratio of the number of teeth on the driving gear to that of the driven gear. For example, a small gear driving a larger gear will reduce speed but increase torque. This principle is widely used in automatic transmissions in vehicles, where the system continuously adjusts gear ratios to optimize performance while driving.

2. Belt and Chain Drives

Belt and chain drives are alternative methods that provide flexibility in design and application. These systems use a belt (flat or V-shaped) or a chain to link two or more rotating shafts. While chains tend to offer higher torque transfer capabilities and efficiency, belts are quieter and require less maintenance. Both systems have advantages and disadvantages depending on the application, such as requiring minimal space or handling high loads.

speed transmission

For example, in motorcycles, chain drives are prevalent due to their robustness and ability to handle high-speed operation. On the other hand, belt drives are often favored in applications like lawnmowers and certain types of conveyor systems, where noise reduction and smooth operation are essential.

3. Hydraulic Systems

Hydraulic transmissions employ fluid mechanics to transmit power efficiently. These systems use pressurized fluid to engage a motor or piston, converting fluid energy into mechanical energy. This method is highly efficient for applications requiring a significant amount of power transfer in a compact space, such as in construction equipment, flight control systems, and elevators. Hydraulic systems allow for smooth operation and variable speed control, which is vital for precision tasks.

4. Innovations in Speed Transmission

Recent advancements in technology have led to the development of innovative speed transmission systems. For instance, Continuous Variable Transmissions (CVTs) in vehicles allow for an infinite range of gear ratios, resulting in improved fuel efficiency and smoother acceleration. Additionally, the rise of electric vehicles (EVs) has led to new designs that simplify speed transmission by directly linking motors to wheels, further enhancing performance and reducing mechanical losses.

Conclusion

Understanding speed transmission is crucial for optimizing the performance of various systems relying on efficient power delivery. From gears and belts to hydraulic mechanisms, each method has unique advantages that can be applied across multiple industries. As technology continues to advance, we can expect to see more innovative solutions emerging, enhancing the efficiency and efficacy of speed transmission systems in our everyday lives. For engineers and designers, mastering these concepts will increasingly become essential to meet the growing demands for performance, sustainability, and reliability in a rapidly evolving technological landscape.

-

SHACMAN Left Door Lock Assembly | Durable & Reliable ReplacementNewsAug.21,2025

-

LZ504 32 Series Agricultural Tractor: Compact & Powerful Farm WorkNewsAug.19,2025

-

plastic pipe fittings-Chenyang Group|Durable&CustomizableNewsAug.18,2025

-

Plastic Industrial Pipe Fittings - Chenyang Group | Durable, Customizable, VersatileNewsAug.18,2025

-

8T Truck Mounted Crane: Powerful, Versatile Lifting SolutionsNewsAug.18,2025

-

Durable Plastic Pipe Fittings - Chenyang Group | Customizable, VersatileNewsAug.18,2025

Popular products