One of the primary advantages of flame retardant tapes is their application in electrical insulation. In electrical engineering, the use of heat-resistant tapes mitigates the risks associated with overheating wires and components. By providing a protective barrier, these tapes not only prevent short circuits but also safeguard against potential fire hazards. Industries such as automotive manufacturing, aerospace, and electronics heavily rely on these tapes to ensure compliance with safety standards and regulations.

Is Polyethylene Tape waterproof?

Silicone tape is different from silicone sheets. Silicone sheets are used for protecting wounds and scars in medical settings. Silicone sheeting is also used in the food, drink, manufacturing and pharmaceutical industries due to its heat resistance, hygienic qualities and versatility.

The Difference Between Silicone Rubber Tape and Rubber Repair Tape

floor safety strips. They are easy to install and require minimal maintenance, making them a practical solution for reducing the risk of slips and falls. In addition to preventing accidents, safety strips can also help businesses comply with safety regulations and avoid costly liability claims.

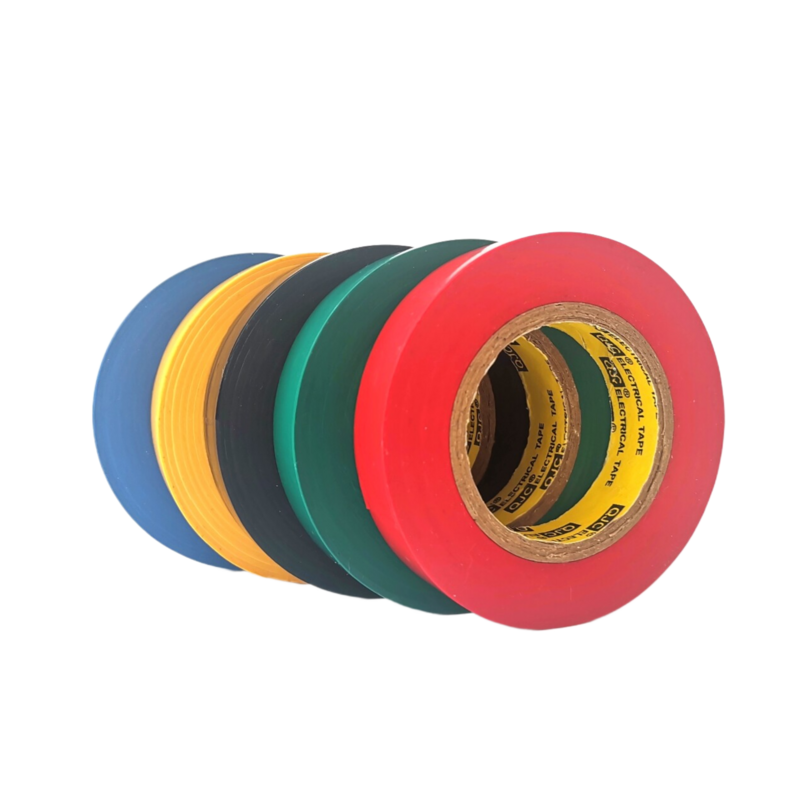

If you love tapes like we do, then you know how important electrical tape is. Today, I want to talk about 3M Rubber Electrical Tapes. As experts in all kinds of tapes we are excited to share our knowledge and enthusiasm for these amazing tapes and the applications they can be used in.

Plastic wiring loom wraps are generally more rigid and durable, making them ideal for protecting wires in areas where they are likely to be exposed to moisture or physical damage. Fabric wraps, on the other hand, are more flexible and breathable, allowing for better airflow and heat dissipation around the wires.

Its specific features include

brown insulation tape. It finds its utility in automotive repairs, plumbing, HVAC systems, and even in sports and fitness for securing athletic gear or providing support to muscles. Its ease of use, combined with its durability, makes it a go-to solution for quick fixes and preventive maintenance tasks.

brown insulation tape. It finds its utility in automotive repairs, plumbing, HVAC systems, and even in sports and fitness for securing athletic gear or providing support to muscles. Its ease of use, combined with its durability, makes it a go-to solution for quick fixes and preventive maintenance tasks.