Security is another cornerstone of GSC367TD. In an era where data breaches and cyber threats are on the rise, the system incorporates robust security measures to safeguard sensitive information. Through encryption and advanced authentication techniques, GSC367TD not only protects data integrity but also fosters trust among users. Organizations can rest assured knowing that their information is secure, allowing them to focus on their core competencies without the constant worry of security vulnerabilities.

Moreover, the inclusion of warranties and customer service support can also reflect on the price. A model that offers comprehensive support and a longer warranty period may come at a premium but can provide peace of mind and added value to the consumer.

When it comes to leather sewing machines, one important component that often goes unnoticed is the sewing machine belt. This small but essential part plays a crucial role in the overall performance of the sewing machine.

Once you're comfortable with needle positioning, explore different stitching techniques to enhance your leather projects. The saddle stitch, for example, requires you to use two needles threaded on either end of a single piece of thread. This method allows for more strength and durability, making it ideal for items subjected to wear and tear. Pay close attention to how you position the needles for this technique. Using the same entry and exit points for both needles will create a beautiful, consistent look.

Heavy-duty jobs like making leather coats or outdoor gear require a lot of power and accuracy. Most of the time, these projects call for thick materials and stitches that are strong and precise. Heavy-duty machines are the best choice for these kinds of jobs because regular machines might be unable to handle them. They are made to work with these things without lowering the quality.

Lastly, do your research on different brands and models of heavy duty sewing machines. Read reviews from other users, compare specifications, and consider factors such as warranty and customer support when making your decision. By taking the time to thoroughly research your options, you can ensure that you are choosing the right heavy duty sewing machine for your specific needs.

5. Durability and Longevity Investing in a high-quality double needle walking foot sewing machine can be a game-changer for those who sew frequently. These machines are built to withstand rigorous use, and their robust construction often means they last longer than standard sewing machines.

Another key benefit of heavy-duty denim thread is its ease of use. Its thickness and strength make it less prone to breaking during the sewing process. For those using sewing machines, this type of thread glides smoothly through the machine, facilitating a more enjoyable sewing experience. Additionally, because heavy-duty denim thread is compatible with various sewing machines, hobbyists and professionals alike can use it without having to invest in specialized equipment.

Understanding Sewing Techniques

At its core, a serger machine is designed to finish the edges of fabric. It combines several functions—trimming, sewing, and overlocking—into one operation. Unlike a traditional sewing machine, which typically uses a single needle and one or two threads, a serger can use multiple threads (usually 3 or 4) to create a secure seam. This capability allows it to produce stitches that not only hold layers of fabric together but also prevent fraying and unraveling.

3. Tents and Canvas Products: Outdoor products like tents, sun shades and backpacks often use sturdy canvas or similar fabrics. extra heavy duty sewing machines can effectively join these materials for waterproof and long-lasting seams.

Using a double needle can be an exciting way to enhance your sewing projects. With a little practice, you'll find it an invaluable tool in creating beautifully finished seams and hems. Whether you're a seasoned seamstress or just starting out, incorporating a double needle into your sewing repertoire can bring new life to your creations. Happy sewing!

Furthermore, many hand sewing machines include a built-in walking foot, which helps to evenly feed multiple layers of fabric through the machine. This is essential in upholstery work to prevent slipping and misalignment, ensuring that the final product is both aesthetically pleasing and structurally sound.

single needle juki sewing machine 8100e price. The Juki 8100e is also easy to maintain, with simple cleaning and lubrication procedures that can be done at home.

The Versatility of the Dressmaker Zig Zag Sewing Machine

4. Quality of Stitches The even feeding mechanism results in straighter, more evenly spaced stitches, which enhances the overall quality of your finished project. This is particularly important for intricate designs and quilts.

walking foot sewing machine for sale

Cutting line sewing, often referred to as pattern making or garment construction, is a fundamental aspect of the fashion industry that combines creativity with precision. This essential process is the backbone of creating beautifully tailored clothing, ensuring that each piece not only fits the wearer perfectly but also reflects the designer's vision. In this article, we will explore the intricate details of cutting line sewing, its significance in fashion design, and some tips for mastering this essential skill.

1. Speed and Efficiency One of the most significant advantages of industrial sewing machines is their speed. While a standard home sewing machine might sew at a rate of 600 stitches per minute, an industrial machine can operate at speeds exceeding 1500 stitches per minute. This increased efficiency is invaluable for those who sew frequently or produce items in larger quantities.

However, if you are looking for a machine that deals with all of these even easier, and more comfortably, and also want to sew up a few patterns you have always wanted to try but are not exactly suited for a basic machine, then a budget, domestic heavy-duty machine is the way to go: an easy to use, simple non-computerized HD sewing machine.

Another key benefit of heavy-duty denim thread is its ease of use. Its thickness and strength make it less prone to breaking during the sewing process. For those using sewing machines, this type of thread glides smoothly through the machine, facilitating a more enjoyable sewing experience. Additionally, because heavy-duty denim thread is compatible with various sewing machines, hobbyists and professionals alike can use it without having to invest in specialized equipment.

The Rise in Popularity and Pricing of Fully Automatic Sewing Machines

The first step in creating car mats is selecting the right materials. The most common fabrics include durable rubber, heavy-duty carpet, and even recycled materials for environmentally conscious creators. Rubber mats provide excellent water resistance and easy cleaning, while heavy-duty carpet can add a touch of style and comfort.

In conclusion, a post bed pattern sewing machine for leather is a valuable tool for anyone who works with leather materials. Its unique design, powerful motor, and precise stitching capabilities make it an essential investment for leather crafters and sewers. If you are looking to take your leather crafting to the next level, consider investing in a post bed pattern sewing machine for leather. Your projects will benefit from the enhanced precision, efficiency, and quality that this type of sewing machine provides.

Heavy-duty leather sewing machines are designed to handle tough materials normally used in leather crafting. These machines have robust construction and powerful motors that can easily sew through multiple layers of leather, thick fabrics, and other heavy materials. Unlike standard sewing machines, heavy-duty models come equipped with more powerful needles and feed systems that allow them to manage challenging materials smoothly.

The price of zigzag sewing machines can vary widely depending on the above factors. Entry-level machines are typically priced between $100 to $300. These models often provide basic zigzag functionality suitable for beginners and light sewing tasks. Mid-range machines usually cost between $300 to $700 and include more advanced features, making them suitable for hobbyists and semi-professionals. High-end machines, which may be priced from $700 to over $2,000, are designed for serious sewing enthusiasts and professionals, offering extensive features, durability, and high performance.

Auto sewing refers to the use of advanced robotics and computerized technology to perform sewing operations with minimal human intervention. Traditionally, sewing was a labor-intensive task, relying heavily on skilled workers to produce garments. However, with advancements in artificial intelligence (AI), machine learning, and robotics, auto sewing systems can now replicate these skills with remarkable precision.

When searching for leather sewing machines for sale, there are several key features to consider

Another noteworthy aspect of cylindrical bed sewing machines is their adaptability to different sewing materials. Whether the fabric is lightweight like chiffon or heavier like denim, these machines can be adjusted to ensure optimal stitch quality. The ability to switch between different types of materials without compromising performance makes cylindrical bed sewing machines a favorite among manufacturers who deal with diverse product lines.

A bag closing sewing machine head operates by stitching the open ends of bags, which can vary from simple paper sacks to complex multi-layered polyethylene bags. The design of these sewing machine heads is tailored to handle different materials, providing versatility and adaptability in manufacturing processes. Equipped with advanced technology, many modern bag closing sewing machine heads come with adjustable stitch lengths and tension controls, allowing operators to customize the stitching process according to the specific requirements of the material being used.

Another benefit of an easy-to-use heavy-duty sewing machine is its versatility. These machines can handle a wide range of fabrics, from delicate silks to heavy denim, and can sew a variety of stitches, from basic straight stitches to intricate embroidery designs. This versatility allows users to take on a wide range of projects without having to switch machines.

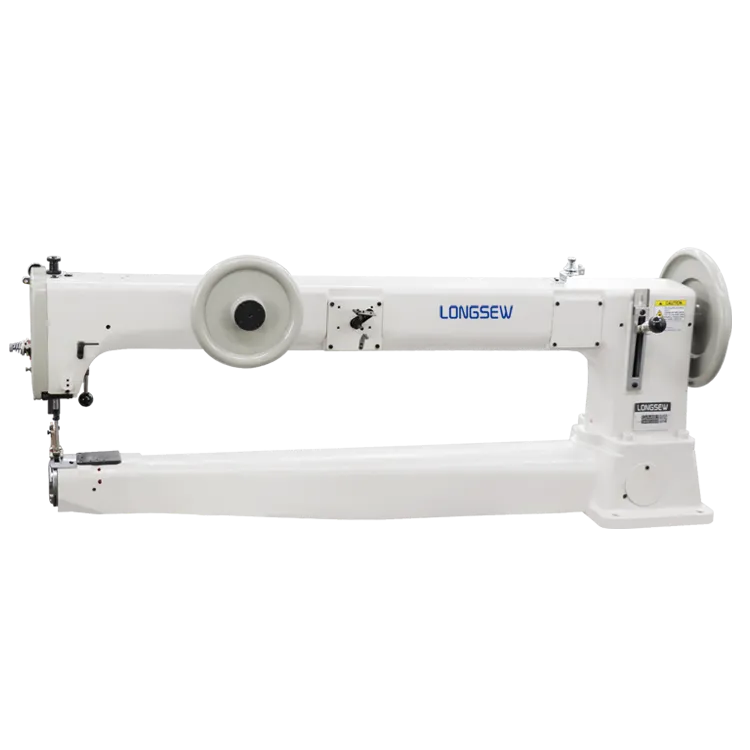

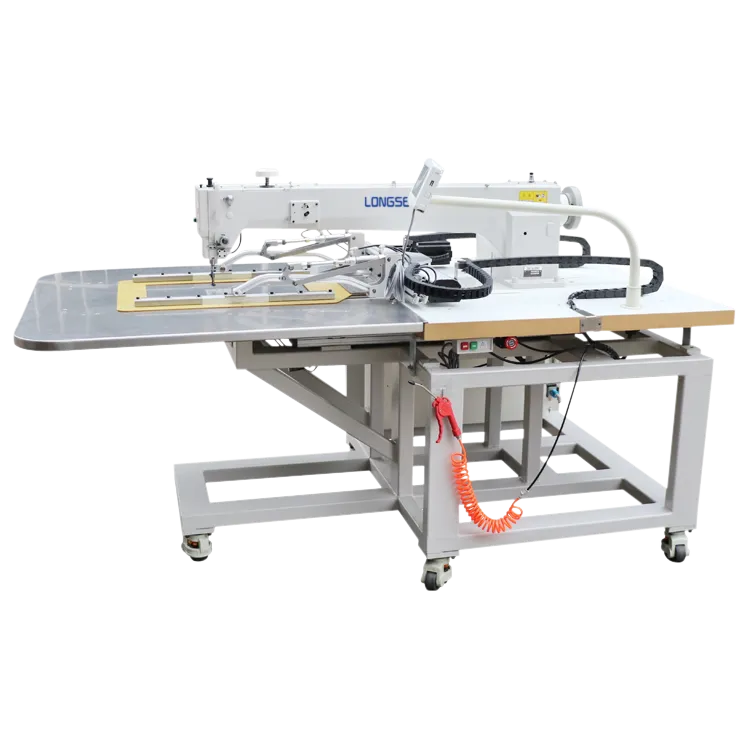

Industrial Long Arm Sewing Machines for Sale A Comprehensive Guide

Feed dogs are the teeth-like mechanisms on a sewing machine’s needle plate that help guide the fabric through as you sew. When dealing with light fabrics, there’s a potential risk of these feed dogs snagging or pulling the material, leading to damage or misalignment. Light fabrics, being delicate, may get caught in larger feed dogs intended for heavy materials.

4. Cost-Effective Although the initial investment in an industrial overlocker may be higher than a standard sewing machine, the long-term benefits, including reduced labor costs and improved fabric usage, can lead to significant savings.

industrial overlocker for sale

The journey of the walking needle sewing machine began in the early 20th century as the demand for more efficient sewing techniques grew in response to the booming textile industry. Before its invention, conventional sewing machines relied on fixed needles and feed mechanisms, which often resulted in uneven stitches and difficulty handling multiple layers of fabric. The introduction of the walking foot mechanism revolutionized the sewing process, allowing the needle and the fabric to move simultaneously. This not only improved the precision of stitching but also enhanced the machine’s ability to sew challenging materials, such as leather and heavy fabrics.