Combining style with functionality, the Chrysler Pacifica offers a luxurious interior and innovative technology. It features Stow 'n Go seating, which allows seats to fold into the floor to maximize cargo space when needed. This flexibility, along with its advanced safety features, makes the Pacifica a formidable contender in the minivan category.

Moreover, HPMC is also used in the manufacturing of paints, adhesives, and detergents. It improves the performance and quality of these products by enhancing their viscosity, adhesion, and dispersion properties. HPMC is compatible with other additives and ingredients, making it a versatile ingredient in various formulations.

Food Industry Applications

Factors Influencing HPMC Density

5. Applications in Formulation Understanding HPMC solubility through these charts is crucial for formulators in the pharmaceutical and food industries. For instance, in pharmaceutical tablets, HPMC is often used as a coating agent for controlled release. The specific solubility characteristics dictate how quickly the tablet breaks down and releases the active ingredient, ensuring proper dosing and effectiveness.

Understanding HPMC

5. Textile Industry HEC is employed in textile printing and finishing processes to improve the formulation's viscosity and ensure uniform application.

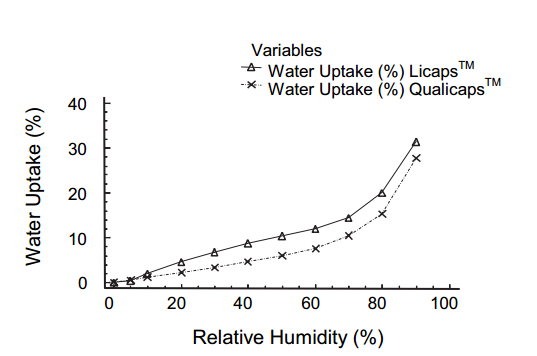

Several materials have been tested as a substitute for gelatin capsules. Hydroxypropylmethylcellulose (HPMC) has become a successful alternative material for two-piece capsules and is used for supplements all over the world.

Why Buy Hydroxyethyl Cellulose?

Despite these challenges, the overall outlook for HEC pricing remains cautiously optimistic. Innovations in cellulose sourcing and production can lead to future cost efficiencies. Furthermore, the push for sustainable and eco-friendly products is likely to sustain demand for HEC in niches that prioritize bio-based ingredients.

4. Self-Leveling Compounds RDPs play a vital role in self-leveling compounds by helping maintain workability while ensuring good adhesion to the substrate. This property is essential for achieving a smooth, even surface.

HPMC is also widely used in construction materials, such as cement, mortar, and tile adhesives. Its water-retention properties ensure that these mixtures remain workable for extended periods, allowing for improved adhesion and reduced cracking during the curing process. This has made HPMC a crucial component in producing high-quality, durable building materials.

Understanding HPMC

HPMC is synthesized by the modification of cellulose using propylene oxide and methyl chloride, resulting in a product that combines properties of both cellulose and synthetic compounds. This modification enhances its solubility in water and ability to form gels at low concentrations. HPMC is characterized by its excellent film-forming capabilities, temperature stability, and tolerance to electrolytes, making it suitable for various formulations.

hpmc viscosity grades. By selecting the appropriate viscosity grade of HPMC, formulators can achieve the desired drug release profile, whether it is immediate, sustained, or extended release. Additionally, the viscosity of HPMC can also influence the strength and disintegration of tablets, as well as the stability of suspensions and emulsions in liquid formulations.

Understanding Hydroxypropyl Methylcellulose Powder Properties and Applications

Performance Characteristics

In conclusion, HPMC powder is a powerful and adaptable polymer that has carved a niche for itself in various sectors. From enhancing construction materials to being integral in pharmaceuticals, food processing, and cosmetics, its multifaceted applications are a testament to its remarkable properties. Continued advancements in research and development are expected to further unlock its potential, driving innovation and sustainable practices across multiple industries. As businesses increasingly prioritize performance and environmental impact, HPMC’s relevance will undoubtedly grow, making it a key player in the future of various applications.

WHY IS IT USED?

One of the most significant advantages of incorporating HPMC into wall putty formulations is improved workability. HPMC influences the rheological properties of the putty, providing a creamy texture that makes it easy to apply with trowels or rollers. The smooth consistency reduces the effort required for application, minimizing the risk of uneven surfaces or marks.

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose ether widely used in various industries due to its unique properties. As a non-ionic polymer derived from natural cellulose, HPMC has gained significant attention for its thickening, emulsifying, and film-forming abilities. Its applications span across pharmaceuticals, food, construction, and personal care, highlighting its importance in everyday products and industrial processes.

5. Respiratory Issues Inhalation of HPMC dust, particularly in occupational settings, can lead to respiratory issues such as irritation of the throat and lungs. While this is primarily a concern for workers who handle the raw material in powdered form, caution is advised for anyone who may be exposed to airborne HPMC.

In conclusion, Hydroxypropyl Methylcellulose (HPMC) is a versatile and effective additive in the formulation of detergents. Its multifunctional properties—as a thickener, stabilizer, film former, and soil suspending agent—enhance the overall cleaning performance and user experience of detergent products. Additionally, its biodegradable nature makes HPMC an attractive option in the context of sustainable manufacturing practices. As the demand for high-performance and environmentally friendly cleaning solutions continues to grow, HPMC is poised to play an increasingly important role in the detergent industry. Manufacturers who recognize the benefits of incorporating HPMC into their formulations may find themselves at the forefront of innovation in cleaning technology.

1. Raw Material Costs The primary raw materials for producing RDP powders are monomers, which are influenced by the prices of crude oil and natural gas. Fluctuations in these commodity prices can lead to corresponding changes in RDP powder pricing.

5. Environmental Benefits

2. Pharmaceuticals In the pharmaceutical industry, HPMC serves as a crucial excipient. It is commonly used in the formulation of controlled-release drug systems and tablets, owing to its ability to form gels and control drug release rates. Additionally, HPMC contributes to the stability and bioavailability of various pharmaceutical products.

Dissolution Speed

Conclusion

Hydroxypropyl methylcellulose is a uniquely soluble polymer with wide-ranging applications driven by its solubility properties. Understanding the factors influencing HPMC solubility is crucial for optimizing its use in various formulations, ensuring efficient delivery and performance. As industries continue to evolve, the significance of HPMC will likely grow, driving innovation and enhancing product efficacy across multiple fields.

Understanding Hydroxyethyl Cellulose

Viscosity is another area where HEC and HPMC diverge. HEC generally produces a lower viscosity compared to HPMC when used at equivalent concentrations. This is particularly advantageous in applications where a lower viscosity is desired, such as in certain cosmetic formulations. HPMC, with its superior thickening ability, is often preferred in formulations that require enhanced texture and stability.

hec vs hpmc

Additionally, HPMC's ability to form foams and gels makes it an attractive option for creating low-calorie alternatives to foods. With the rising demand for healthier food options, the application of HPMC in reformulating traditional recipes has gained significant traction in recent years.

Hydroxyethylcellulose A Comprehensive Analysis of Price Dynamics

hpmc grades pdf.

hpmc stands for. This is particularly useful in façade coatings, wall paints, and joint compounds, where a protective barrier is needed to maintain the appearance and longevity of the material.

HPMC is a derivative of cellulose, where hydroxylpropyl and methyl groups are introduced into the cellulose structure. This modification enhances the solubility of cellulose in water and imparts various beneficial attributes. HPMC gels are often favored because they are non-toxic, biodegradable, and can form gels at different temperatures and pH levels, making them highly versatile.

1. Construction In the construction sector, HPMC is often incorporated into tile adhesives, mortars, and joint compounds. Its water retention properties enhance workability, allowing for longer open times and improved adhesion.