1. Space Industrial sewing machines tend to be larger and heavier than standard home machines. It's essential to ensure that you have enough workspace to accommodate the machine and allow for comfortable movement while sewing.

Reduced Error and Waste

When shopping for a single needle quilting machine, it's also important to consider the warranty and customer support provided by the manufacturer. Since quilting machines are complex pieces of equipment, it's important to have access to technical support and repairs if needed. Some brands offer extended warranties and customer service hotlines to assist with any issues that may arise.

Most modern lock stitch machines are equipped with advanced features such as automatic threading, programmable stitch lengths, and different stitch patterns. These enhancements significantly increase productivity and accuracy, accommodating various sewing needs.

In addition to fashion, double needle machines are also utilized in home textile production, such as curtains, bed linens, and upholstery. Their capability to handle thick fabric layers makes them ideal for sewing heavy materials, ensuring a strong and lasting hold. Moreover, in industrial applications, double needle machines can be employed in manufacturing items such as bags, sails, and protective clothing, where durability is paramount.

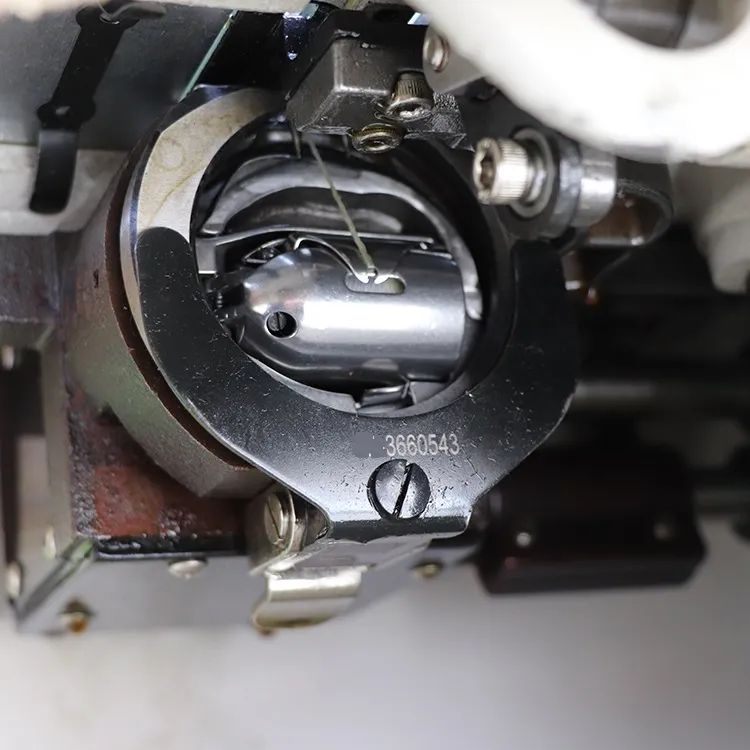

industrial double needle sewing machine

Despite their numerous advantages, the transition to CNC upholstery sewing machines can present challenges. The initial investment in high-quality CNC machines can be substantial, making it a significant consideration for smaller companies. Furthermore, the integration of advanced technology into existing workflows may require retraining staff, which can be met with resistance. Businesses must weigh the long-term benefits against these initial hurdles to determine if CNC technology is the right fit for their operations.

Finishing Up

Conclusion

Consider a fictional example: Sarah, a budding fashion designer, started with a standard machine. Over five years, she spent an average of $100 annually on maintenance, and by the sixth year, she had to replace the machine, costing her another $400—her total expenditure over six years: $1000.

A heavy duty basic sewing machine is specially designed to handle a wide range of fabrics, including thick and heavy materials such as denim, canvas, and upholstery fabric. Unlike standard sewing machines, which may struggle with these tougher materials, heavy duty machines come equipped with stronger motors, reinforced structures, and specialized stitching capabilities that make them ideal for demanding sewing projects.