Fortunately for you, there are measures that you can take to ensure that you have little to no problems with your well’s water system.

3. Durability and Flexibility The tape needs to maintain its integrity under mechanical stress. It should be flexible enough to wrap around busbars securely while also being tough enough to resist wear and tear over time.

Generally speaking, manufacturers use three different adhesive types in combination with the backing material to produce a final “tape” product. Though these adhesive types can be subdivided into subgroups, the main categories are as follows:

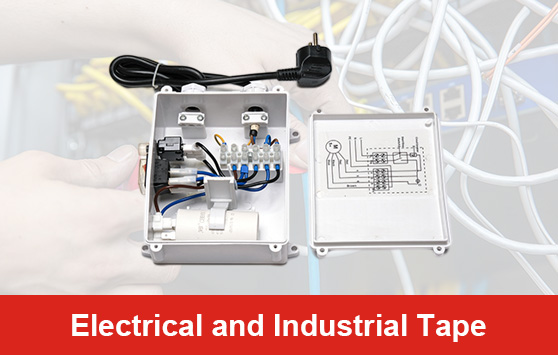

Price is an important factor when choosing a control box because there are many that are cheap but are also faulty.

One of the most significant advantages of self-fusing rubber tape is its remarkable flexibility. It can be stretched and molded to fit a wide array of shapes and surfaces, making it ideal for bundling wires, sealing leaks, and wrapping hoses. Additionally, it retains its elasticity over time, allowing it to accommodate movement without breaking or peeling away.

For applications that require a higher level of water resistance or waterproofing, specialized tapes or additional measures may be necessary. It’s recommended to assess the specific requirements of your application and consider the expected level of water exposure to determine whether polyethylene tape alone provides sufficient water resistance or if additional waterproofing measures are necessary.