- In industrial settings, the tape's self-fusing nature simplifies complex installations. It can be used to create robust gaskets for machinery or to wrap around pipes and valves to prevent leaks. The tape's consistency ensures that each application is uniform, reducing the risk of failure points that could compromise the integrity of a system.

The Versatile Utility of Flex Tape A Comprehensive Look at Flex Tape White 4x5

5. Test the Seal Once applied, check to see if the seal is tight. You can do this by attempting to slide a piece of paper between the door or window and the frame; if it doesn’t slide out easily, your installation was successful.

Seal out moisture from electrical connections

grey pvc tape. The tape's resistance to oils and chemicals makes it suitable for use in engine compartments and other areas where exposure to harsh substances is common.

Corrosion resistance – the dielectric strength of electrical tape is a measure of its electrical strength as an insulator. Vinyl electrical tape is available with differing dielectric strength making it ideal to use for insulating high-voltage wires over extended periods of time. By comparison, PVC electrical tape can be used in similar situations but care should be taken that its dielectric strength is sufficient to insulate active wires.

Rubber tape usually does not have an adhesive side but sticks to itself. This means it has to be stretched entirely around a cable to effectively adhere to itself using elastic tension against the backing.

self amalgamating tape waterproof. It can withstand extreme temperatures, ranging from -40°C to 120°C, making it an ideal choice for outdoor applications. Its water-resistant properties prevent moisture and other contaminants from penetrating the seal, ensuring long-lasting protection.

self amalgamating tape waterproof. It can withstand extreme temperatures, ranging from -40°C to 120°C, making it an ideal choice for outdoor applications. Its water-resistant properties prevent moisture and other contaminants from penetrating the seal, ensuring long-lasting protection.However, it’s important to note that the water resistance of Polyethylene Tape can vary depending on the specific formulation, thickness, and adhesive used. While it can withstand occasional exposure to water or damp environments, it may not be suitable for long-term immersion or continuous exposure to water.

Its resistance to temperature fluctuations, vibrations, and chemicals makes it an ideal choice for ensuring a secure and long-lasting seal Its resistance to temperature fluctuations, vibrations, and chemicals makes it an ideal choice for ensuring a secure and long-lasting seal

Its resistance to temperature fluctuations, vibrations, and chemicals makes it an ideal choice for ensuring a secure and long-lasting seal Its resistance to temperature fluctuations, vibrations, and chemicals makes it an ideal choice for ensuring a secure and long-lasting seal butyl rubber sealant black.

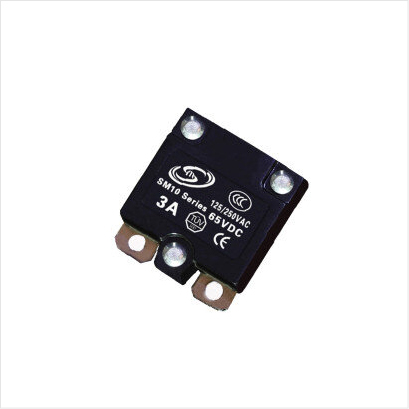

butyl rubber sealant black.Electrical control boxes are endowed with electrical components such as circuit breakers and transformers since they are engineered to oversee electrical distribution. Their application range and scope transcend both industrial and residential use. Common examples of electrical control boxes include;