Inhalation of hydroxypropyl methylcellulose dust—often a risk in industrial settings—can lead to respiratory problems such as coughing, wheezing, and shortness of breath

. People with pre-existing respiratory conditions, such as asthma or chronic obstructive pulmonary disease (COPD), should take caution when around airborne HPMC and consider using protective measures, such as masks or respirators, if working in environments where dust is prevalent.What is HPMC?

HEC is known for its excellent water retention, film-forming ability, and thickening properties. It is non-ionic, meaning it has no charge, which allows it to be compatible with a wide range of other substances in formulations. One of the most beneficial properties of HEC is its capacity to create viscous solutions even at low concentrations. This characteristic is particularly important in formulations requiring a specific viscosity for optimal performance. Moreover, HEC is stable across a wide pH range, further increasing its applicability.

Redispersible polymer powder manufacturers are pivotal in shaping the future of the construction industry. By providing high-quality, versatile products, these manufacturers meet the evolving demands of builders and architects. As technology advances and sustainability becomes a central focus of construction practices, the role of RDPs will only grow, contributing to more durable and efficient building materials. For companies involved in construction and material supply, collaborating with reputable RDP manufacturers can lead to significant advantages in product performance and overall project success.

HPMC's ability to improve texture and stability makes it a valuable ingredient in the food sector. It acts as a thickener, stabilizer, and emulsifier, enhancing the mouthfeel of food products without contributing any calories or fat. Common applications include salad dressings, sauces, ice creams, and gluten-free baked goods, where it helps to mimic the texture provided by gluten.

redispersible polymer powder types

HPMC plays a crucial role in enhancing the adhesion properties of wall putty. It allows the putty to bond effectively to various substrates, including concrete, plaster, and gypsum. This strong adhesion is vital for preventing peeling or cracking, ensuring a long-lasting finish. HPMC's ability to retain moisture also aids in the curing process, further enhancing the bonding strength.

In the construction industry, MHEC is widely used as a thickening agent in cement-based formulations such as tile adhesives, grouts, and plaster. Its property of enhancing the workability of mortars and improving water retention makes it indispensable in construction applications. MHEC allows for longer open times, ensuring that tile setters have ample time to adjust tiles before the adhesive sets. Furthermore, MHEC helps prevent sagging in vertical applications, contributing to the overall durability and quality of the structure.

methyl hydroxyethyl cellulose manufacturers

HPMC Manufacturers in China

If you prefer to buy hydroxyethyl cellulose locally, check out chemical distributors or suppliers in your area. Many cities have chemical supply stores or industrial supply companies that carry HEC and other raw materials. Visiting these stores allows you to speak directly with sales representatives who can provide insights and recommendations based on your application.

In the cosmetics and personal care sector, MHEC is valued for its thickening and stabilizing properties. It is commonly found in lotions, shampoos, and creams, contributing to the product's viscosity and sensory profile. Its ability to retain moisture makes it an excellent choice for hydrating formulations, catering to the growing market for skin and hair care products that prioritize hydration and nourishment.

1. Construction Industry One of the most significant applications of HPMC is in the construction sector. It is widely used as a thickening agent in mortars, tile adhesives, and plasters. HPMC enhances workability, prolongs open time, and improves adhesion properties, making it an indispensable component in modern construction materials.

One of the key features of dispersible polymer powders is their ability to enhance the properties of the end product. For instance, they can improve adhesion, flexibility, durability, and water resistance. Additionally, their formulation can be adjusted to achieve specific characteristics, such as controlled release in pharmaceutical applications or enhanced gloss in coating formulations.

Conclusion

Open time refers to the period during which the wall putty remains workable after application. By incorporating HPMC, manufacturers can extend the open time of the putty. This feature facilitates better finishing and allows the applicator to correct any imperfections without being rushed, leading to a smoother and more professional outcome.

2. Improved Workability When included in dry-mix mortars, the powder improves the workability of the mixtures. This means that contractors can apply the materials more easily, achieving smoother finishes and reducing labor time.

china redispersible powder

HPMC Powder A Versatile Polymer for Industrial Applications

Factors Influencing RDP Powder Prices

Applications Across Industries

In the pharmaceutical industry, HPMC is often used as a lubricant in eye drops and contact lens solutions. While it serves this purpose effectively, individuals might experience temporary symptoms of irritation, such as redness, itching, or a burning sensation, upon exposure to HPMC-containing eye products. If these symptoms persist or worsen, it is advisable to consult an eye care professional.

hydroxypropyl methyl cellulose side effects

- Versatility HPMC's various grades and forms mean it can be customized for different applications, providing manufacturers with flexibility in formulation.

- Water Resistance VAE redispersible powder imparts water-repellent properties to mortars and coatings, protecting them from moisture-related issues such as degradation and mold growth.

Potential Risks in Sensitive Populations

In conclusion, HPMC, or Hydroxypropyl Methylcellulose, stands out as a multifaceted polymer with diverse applications across several industries, including pharmaceuticals, food, construction, and cosmetics. Its unique properties, such as solubility, thickening, and film-forming abilities, make it a crucial ingredient in achieving desired product performance. As research and innovation continue to evolve, HPMC's significance is likely to grow, further enhancing its role in various fields and applications.

2. Regulatory Compliance Stringent regulations regarding construction materials, particularly concerning VOC (volatile organic compounds) emissions, can pose challenges for manufacturers. Ensuring compliance while maintaining product performance is crucial.

hydroxyethyl cellulose viscosity concentration. The concentration of HEC in these products is carefully controlled to achieve the desired texture and mouthfeel. Higher concentrations of HEC result in a thicker, more viscous product, while lower concentrations produce a thinner consistency.

Chemical property

Composition and Properties

Market competition also affects pricing dynamics. The HPMC market features various players, from small manufacturers to large multinational companies, each adopting different pricing strategies based on their production capabilities and market positioning. Competitive pricing can drive down prices in some instances, while monopolistic tendencies can lead to price hikes, emphasizing the importance of market structure in understanding price fluctuations.

Hydroxypropyl methylcellulose (HPMC) is a cellulose derivative widely used in pharmaceutical formulations due to its unique properties, which include high viscosity, film-forming ability, and stability. This polymer is commonly employed in a variety of dosage forms, including tablets, capsules, and topical applications. Its versatility makes it an essential excipient in both immediate-release and controlled-release formulations.

One of the primary advantages of redispersible polymer powders is their ability to improve the mechanical properties of end products, such as enhanced adhesion and flexibility

. In construction materials, RPPs provide better bonding between components, which is crucial in applications like tile adhesives, cementitious mortars, and facade coatings. Additionally, RPPs contribute to the durability of these materials, making them more resistant to weathering, humidity, and temperature changes.In construction, HEC serves as a crucial ingredient in adhesives, mortars, and sealants. Its thickening and water-retention capabilities improve the workability of these materials, allowing for better performance during application and curing. HEC helps to enhance the adhesion and flexibility of construction materials, ensuring durability and longevity.

Conclusion

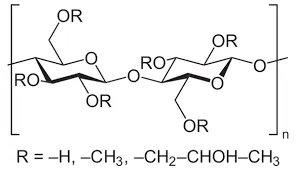

HPMC is derived from cellulose, a natural polymer that is the main component of the cell walls in plants. Cellulose itself is a complex carbohydrate made up of long chains of glucose molecules. To produce HPMC, cellulose undergoes several chemical processes, transforming it into a derivative that has hydroxypropyl and methyl functional groups. This modification is crucial for enhancing the solubility and functionality of the polymer.

However, as with any substance, potential adverse effects can arise under certain conditions. Allergic reactions, though rare, may occur in individuals with heightened sensitivities. Furthermore, excessive consumption or exposure may lead to gastrointestinal discomfort or disturbances. Therefore, it is essential for manufacturers to conduct thorough testing and ensure compliance with safety regulations.

4. Cosmetics and Personal Care

3. Organic Solvents While HPMC is primarily water-soluble, the chart also provides insights into its solubility in organic solvents. Grades of HPMC may exhibit varying degrees of solubility in organic solvents like ethanol or methanol, which can aid in the formulation of certain products, especially in the cosmetic or food industries.