When using electrical tape, it is important to choose the right size and thickness for the job.

- Safety marking tape is typically made from high-visibility materials such as vinyl or polyester, which allows it to be easily seen even in low-light conditions. The tapes are available in a wide range of colors, each with its own specific meaning. For instance, orange and yellow tapes are commonly used to indicate potential hazards or areas requiring special attention, while red tapes are used to mark emergency exits or stop signs.

- Moreover, safety marking tape can also serve as a visual reminder of important safety protocols and procedures. For example, tapes marked with instructions such as Wet Floor or Caution High Voltage can help prevent slips and falls or electrocution by alerting workers to potential hazards.

- Roofing Repairs Sealing leaks in roofing systems, protecting against water infiltration, and extending the lifespan of roofs.

Polyethylene Tape, or PE Tape, is a type of adhesive tape made from polyethylene, a durable and versatile thermoplastic polymer. It finds a wide range of applications due to its various properties and benefits.

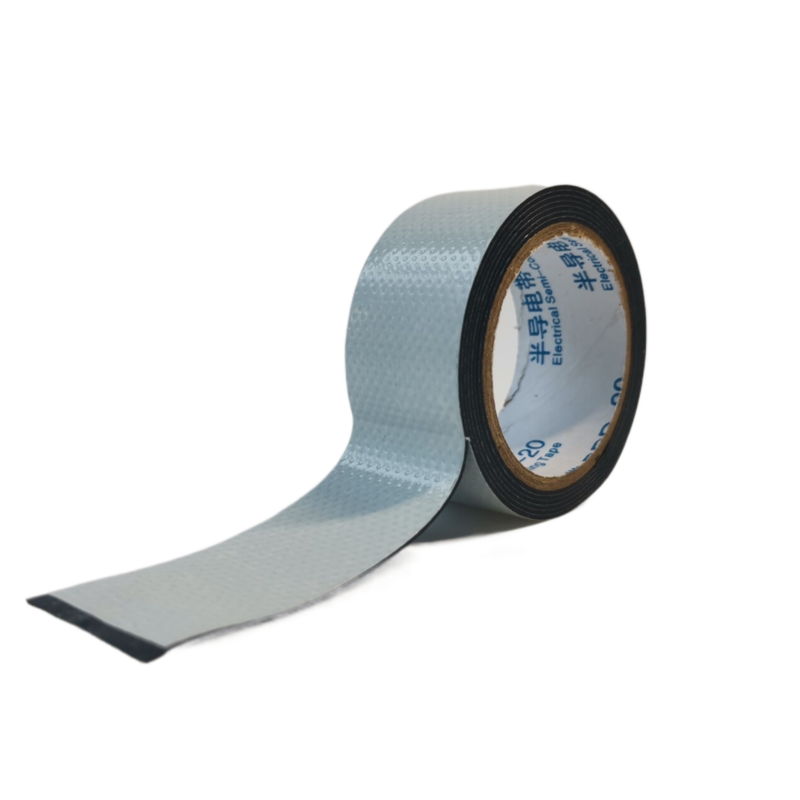

Self-bonding rubber tape, often referred to merely as rubber tape, is an innovative solution that has transformed the way we think about sealing, insulating, and repairing various materials. This unique type of tape is characterized by its ability to bond to itself without the need for adhesives, making it an invaluable tool in numerous applications, from electrical work to plumbing and beyond.

In the industrial landscape, control boxes are the linchpins of efficiency and safety. Here’s how:

Anyone who’s left a roll of general purpose vinyl tape in the cab of their truck on a very hot summer day can attest to the fact that heat makes the adhesive soft. Extreme heat makes it ooze and flow.

Alternatives to electrical tape include heat shrink tubing and wire connectors. Heat shrink tubing is usually used for applications with lower gauge wiring, such as smaller electrical circuits, and wire connectors are used at the ends of stripped wires. Other types of adhesive tape should not be used as a substitute for electrical tape as they will not have the thermal efficiency of a dedicated electrical tape and can therefore be unsafe to use in such situations.

The 19mm width of the tape provides enough space for clear and visible color-coding The 19mm width of the tape provides enough space for clear and visible color-coding

The 19mm width of the tape provides enough space for clear and visible color-coding The 19mm width of the tape provides enough space for clear and visible color-coding pvc tape 19mm.

pvc tape 19mm.Moisture Control

Each of these adhesive types have advantages and disadvantages which make them more or less suitable for particular applications. Here we will draw the major lines outlining these differences.

automotive fabric tape. This tape is engineered to withstand the wear and tear of daily use, making it a reliable long-term solution for any interior fabric repairs or upgrades. From resisting abrasions to repelling moisture and stains, automotive fabric tape is a resilient and long-lasting choice for automotive applications.

automotive fabric tape. This tape is engineered to withstand the wear and tear of daily use, making it a reliable long-term solution for any interior fabric repairs or upgrades. From resisting abrasions to repelling moisture and stains, automotive fabric tape is a resilient and long-lasting choice for automotive applications.3. Durability and Longevity Fireproof gasket tape is engineered to stand the test of time. It is resistant to degradation caused by UV light, moisture, and extreme temperatures, ensuring a long-lasting seal that minimizes the need for frequent replacements. This durability is particularly beneficial in harsh industrial environments, where traditional tapes may fail prematurely.