In the contemporary landscape of manufacturing and packaging, the efficiency and reliability of machinery play a crucial role in meeting production demands. One such machine that has gained significant attention is the bulk bag sewing machine. Designed specifically for the production of bulk bags, also known as FIBCs (Flexible Intermediate Bulk Containers), these machines have transformed the way manufacturers handle large quantities of material, offering speed, precision, and durability.

Moreover, these machines are generally simpler to operate than their electronic or computerized counterparts. While technology has undoubtedly advanced the sewing machine industry, some sewers prefer the straightforward nature of mechanical machines. The manual controls allow users to have more direct engagement with their project, fostering a deeper connection to the craft.

To ensure the longevity of your heavy duty handheld sewing machine, regular maintenance is crucial. After each use, it’s a good practice to clean the machine, removing any lint or debris that may have accumulated. Regularly oiling the moving parts can also help maintain smooth functionality. Furthermore, handle your canvas with care, as excessive pulling or tugging can misalign the fabric and damage stitches.

Conclusion

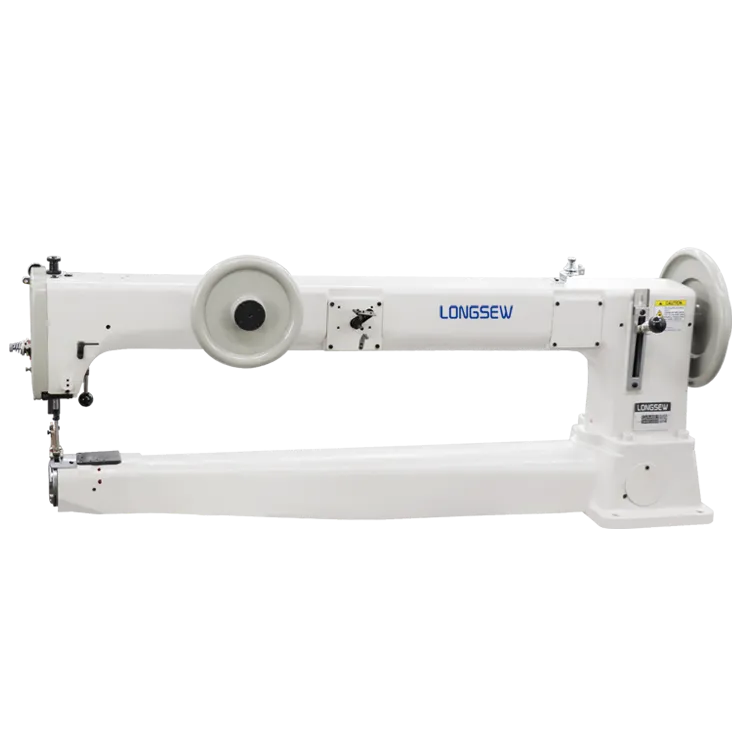

single needle sewing machine price

4. Awls and Punches A leather awl is invaluable for making starter holes, which help guide the needle and prevent the leather from tearing. Hole punches are useful for creating consistent holes in leather for stitching.

sewing through leather

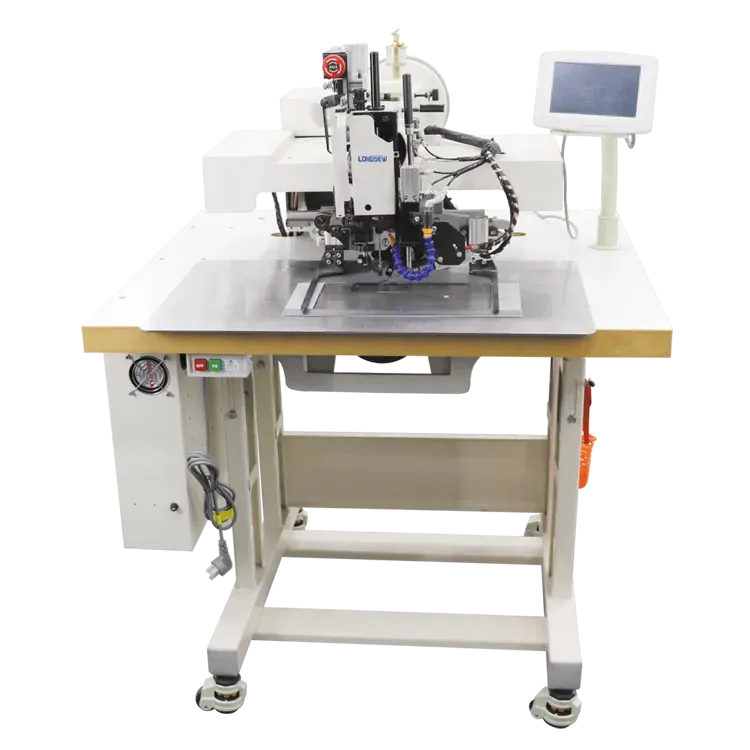

5. User-Friendly Interface Many machines feature digital displays and intuitive controls, allowing operators to easily navigate through settings and options.

Sewing is an age-old craft that has been practiced for thousands of years. Over time, different techniques and styles of sewing have emerged, each with their own unique characteristics and uses. One popular method of sewing is arm sewing, which involves using the arms as the primary tools to create stitches and seams.

3. Robust Construction Machines designed for leather usually feature sturdier build quality. They are equipped with strong motors that can easily penetrate multiple layers of thick leather, making them perfect for projects such as belts, handbags, and wallets.

In conclusion, the walking foot zigzag sewing machine is a valuable investment for anyone serious about sewing. Its ability to accommodate a wide range of fabrics, coupled with the freedom to create intricate zigzag stitches, makes it an indispensable tool in the sewing arsenal. Whether you are crafting a cozy quilt, a fashion-forward garment, or home décor items, this machine enhances your sewing experience, bringing both quality and creativity into every project. As technology continues to evolve, the walking foot zigzag sewing machine remains a timeless companion for seamstresses who value precision, versatility, and artistry.

The two needle stitch, as the name suggests, employs two needles simultaneously to create a pair of parallel rows of stitching. Typically, this technique is executed on a specialized sewing machine equipped with two needles and a twin needle feed, allowing for even and consistent stitching along both lines. This method is particularly popular in the fashion industry, especially in creating garments that require durability and a stylish finish.

Another key advantage of automatic computerized sewing machines is their capacity for precision. The technology behind these machines allows for highly accurate stitching, which is essential for professional-grade garments and intricate craft projects. Features such as automatic tension adjustment and precise cutting mechanisms ensure that seams are even and consistent, contributing to the overall quality of the final product. This level of precision is especially beneficial in the fashion industry, where attention to detail is paramount.

industrial bag sewing machine price. It is important to research and compare different options to find a machine that meets your specific needs and budget. Some factors to consider when choosing an industrial bag sewing machine include the type of bags you will be sewing, the volume of bags that need to be sewn, and the level of automation required.

Understanding the Baffle Sewing Machine

In addition to enhancing efficiency and reducing costs, these machines also prioritize safety and hygiene, especially in industries like food processing. Many automatic bag closer machines are equipped with features that comply with health and safety regulations, mitigating the risk of contamination. By automating the sealing process, the need for human contact with the product is minimized, ensuring that the integrity of the items remains intact.