Metal taps, commonly made from materials like brass, stainless steel, or aluminum, are known for their strength and longevity. The robustness of metal ensures that these taps can withstand higher pressures and temperatures, making them suitable for a broader range of applications. In industrial settings, for example, metal taps are often utilized in pipelines carrying heavy liquids, where durability and reliability are paramount.

For Mill Finish

It is quite a detailed process, which starts with designing every profile.

Mechanical strength and corrosion resistance of this aluminum grade is incredible. You can easily form this grade using conventional methods, but cold-working is seemingly the ideal technique in some tempering conditions.

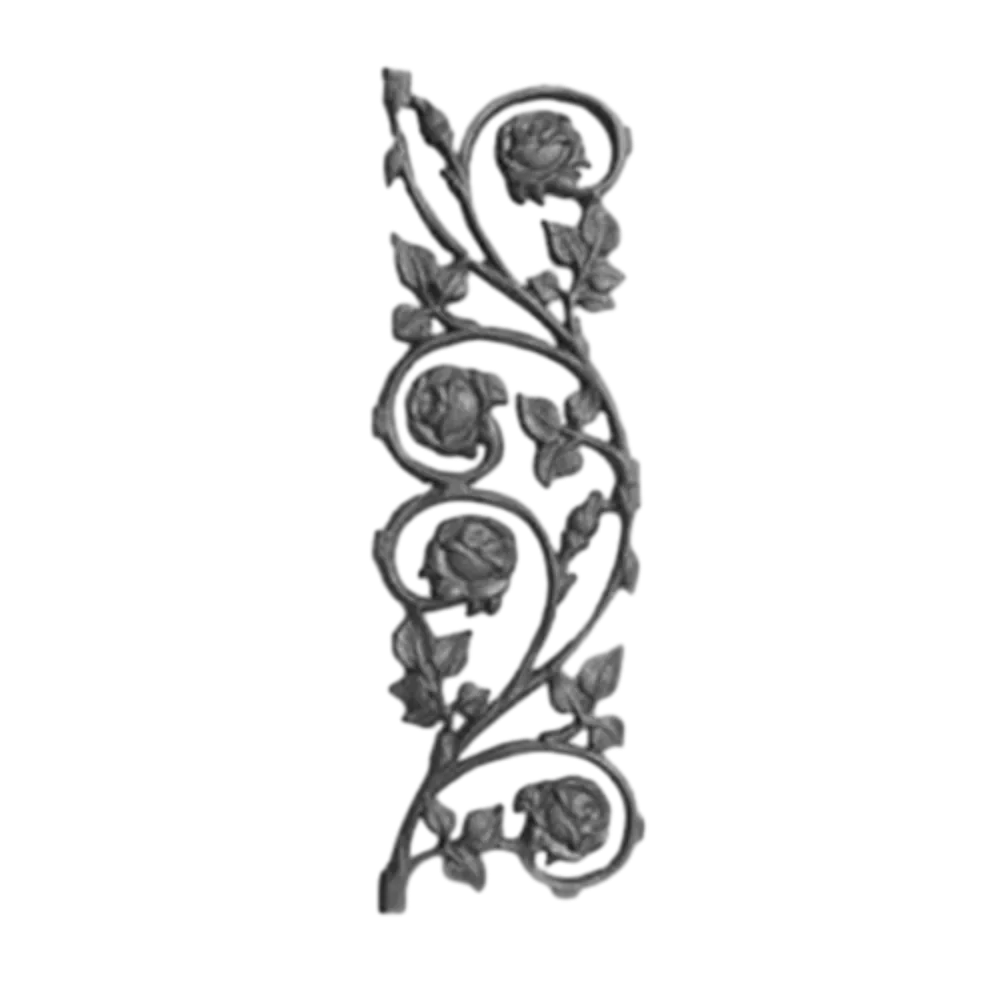

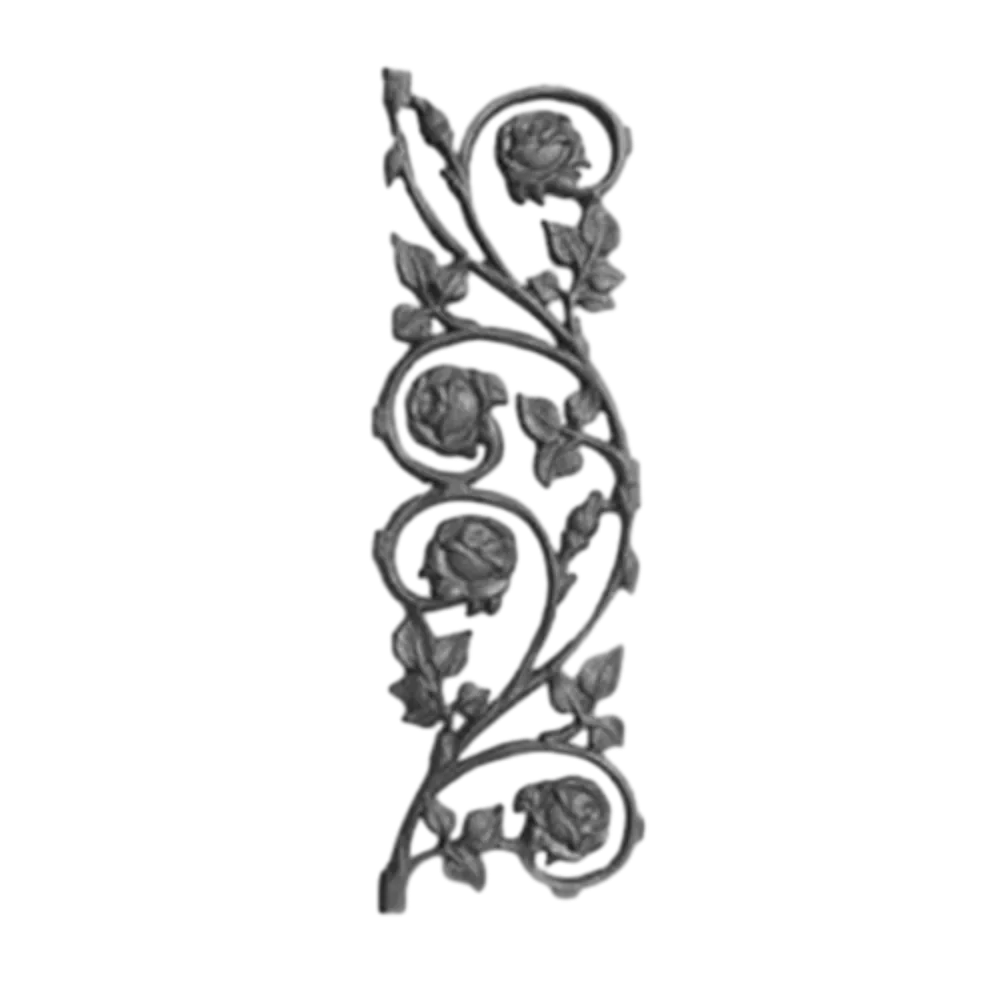

When we’re designing a custom iron fence or railing, we offer customers the option to add decorative elements made from cast iron to an otherwise wrought iron structure. Those pieces are then welded onto the pickets of the railing. This process can save on costs, since producing intricate decorative designs in wrought iron through hand forging can get expensive.

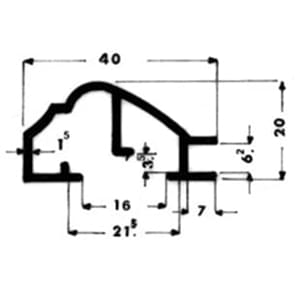

The actual extrusion process involves the following details;

The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme

The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme brushed steel pull handles.

brushed steel pull handles. It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them

It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them stainless steel gate lock box. The box comes with pre-drilled holes for easy installation, and the adjustable mounting brackets allow you to customize the height and angle to suit your specific needs.

stainless steel gate lock box. The box comes with pre-drilled holes for easy installation, and the adjustable mounting brackets allow you to customize the height and angle to suit your specific needs.Thermal insulation aluminum extrusions are important components in any door and window system. It refers to the reinforced polyamide strip between the internal and external aluminum profiles, which forms an insulating barrier in the window frame. More exactly, it makes the aluminum framed window form a barrier between the inner and outer sashes to prevent heat conduction loss.

The versions of cast iron fences with a simpler design provide a more straightforward arrangement to be sturdy, somewhat attractive, and less expensive than the variants with an intricate design.

Furthermore, wrought iron components can be painted or coated with different materials to enhance their appearance and protect them from damage Furthermore, wrought iron components can be painted or coated with different materials to enhance their appearance and protect them from damage

Furthermore, wrought iron components can be painted or coated with different materials to enhance their appearance and protect them from damage Furthermore, wrought iron components can be painted or coated with different materials to enhance their appearance and protect them from damage wrought iron components.

wrought iron components.Wrought iron fence ornaments are more than just decorative elements; they are timeless pieces that add character and elegance to any property. With their rich history, durability, and aesthetic versatility, these ornaments can elevate the allure of traditional and modern homes alike. By incorporating wrought iron into your fencing or landscaping, you not only enhance the visual appeal but also invest in a piece of art that will last for generations. Whether you're drawn to intricate designs or minimalist styles, there’s a wrought iron ornament to suit every taste, ensuring your fence is a true reflection of your unique personality.

The Elegance of Wrought Iron Fence Ornaments

Firstly, ensure you have the right tools on hand. You'll need a screwdriver (both flathead and Phillips, depending on the door), pliers, replacement rollers, and a measuring tape. Replacement rollers can be found at any hardware store or online, with measurements typically provided to ensure a perfect fit.

Iron gates have long been a symbol of grandeur, security, and sophistication, particularly when they serve as the main gate to a property. They not only provide a strong physical barrier but also create an aesthetic appeal that can set the tone for the entire space. The design of a main gate iron gate is a crucial aspect of architectural planning, as it serves as the first impression and a statement of the owner's taste and style.

Finally, in order to build a shed with an aluminium frame profile you need to ensure that you get a good set of plans. These will give you everything that you need so that you can build the shed with minimal hassle. Remember, even the smallest shed can look impressive if you choose the right plan. However, you should always ensure that it is the correct plan that you have purchased. This will make sure that you do not waste any materials and so that you can concentrate on the building process.

One of the most significant advantages of aluminum window frame extrusions is their exceptional durability. Aluminum is inherently resistant to rust, corrosion, and various weather conditions, making it an ideal material for windows that must withstand the elements. Unlike wood, which can warp, rot, or be affected by termites, aluminum maintains its integrity over time. This strength ensures that the window frames will operate smoothly and remain visually appealing for years, reducing the need for frequent maintenance or replacement.

Ensure that the chose aluminum profile meets the design specifications, including the required quality, structural, aesthetics, finish and compatibility with other building materials.

The process of manufacturing aluminium window profiles involves several steps, from raw material selection to final product testing. Here is an overview of the typical process:

We offer a wide and diverse range of windows and doors of top-notch quality, which can satisfy your house or office needs. Our interior and exterior aluminum profiles for doors and windows are of a high value and high utility design to eliminate street noise.

We can offer aluminum door and window extrusion designs.Aluminum has a team of design engineers ready to assist you with custom designs.

In today's highly competitive market in the construction industry, it is crucial to choose high-quality aluminum door and window profile manufacturers. We are committed to creating aluminum profiles that are not only beautiful but also strong and durable. We use high-purity aluminum to ensure that each door and window has excellent corrosion resistance and is not easily deformed. Through precise manufacturing processes, the profiles produced by Aluminum are fully enhanced in strength and stability while ensuring lightness. This means that our products can show excellent performance, whether under the wind pressure test of high-rise buildings or the impact of temperature differences in changing climates.

We understand that modern doors and windows are not just barriers to isolating the internal and external environment; they also represent a pursuit of quality of life. Therefore, Aluminum has launched a series of profile products with fashionable designs, from classic styles to modern fashion, from simple lines to complex patterns, highlighting personality without losing elegance. Furthermore, we offer customized services to ensure that each client's unique needs are met.

Environmental issues are increasingly attracting attention. Aluminum adheres to the green manufacturing concept during the production process. It covers the profile recycling mechanism to reduce the impact on the environment. At the same time, our products have good sealing effects, effectively reduce energy consumption, and contribute to reducing the carbon footprint of buildings.