- Jack and jack stands (if access to the underside is required)

Therefore, the insulation must not only have the dielectric properties we seek but the mechanical strength as well. We want insulation that is:

How to Apply Butyl Rubber Sealant Tape

Types of Control Boxes

2. Cut to length.It is important to have the tape at the correct length before applying it. Once it adheres. it will be difficult to remove.

Conclusion

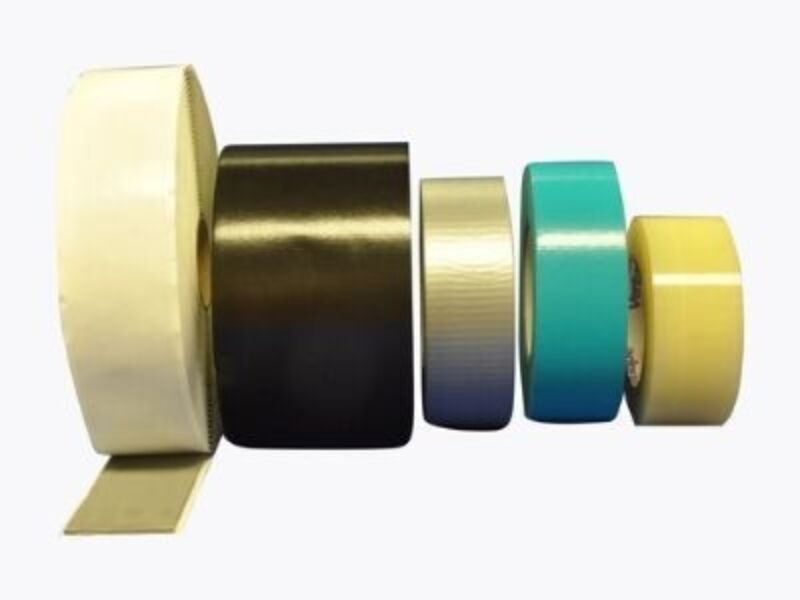

Beyond color-coding, yellow electrical tape is often employed for insulation purposes. It is designed to withstand a certain degree of heat, moisture, and electrical current, making it ideal for insulating electrical connections. For example, when splicing wires together, applying yellow electrical tape around the connection point helps protect it from exposure to environmental elements, preventing moisture from seeping in and causing corrosion. Furthermore, this adds a layer of safety by ensuring that exposed wire does not come into contact with other conductive materials, which could otherwise lead to short circuits or electrical fires.

yellow tape electrical

What’s a light without a light switch, or a TV without a remote? Using technology safely and effectively means having the ability to control it. When it comes to more heavy-duty equipment, the electronics are typically consolidated in one place: the control box.

Solvent-rubber based adhesives have better temperature and aging performance but still poor UV resistance. It is used for electrical and foam tapes.

Bus bar. A common method of insulating a bus bar connection is to first wrap it with two layers of varnished cambric. The subsequent steps consist of four half-lapped layers of rubber or rubber mastic followed by two half-lapped layers of premium vinyl tape.

fireproof tape for fireplace. Its flexible nature allows it to conform to various surfaces, and it remains effective over time without losing its heat-resistant properties. It's a cost-effective solution that can significantly enhance fireplace safety without compromising on aesthetics.

fireproof tape for fireplace. Its flexible nature allows it to conform to various surfaces, and it remains effective over time without losing its heat-resistant properties. It's a cost-effective solution that can significantly enhance fireplace safety without compromising on aesthetics.

how to use self amalgamating repair tape. Make sure to overlap the tape as you wrap it around to ensure a secure bond.

The Versatility and Utility of 3M Vulcanizing Tape