- In warehouse management, for instance, floor tape can denote pallet locations, reducing misplacement and improving inventory control. In manufacturing plants, it can be used to create visual organization systems, guiding employees to their designated work areas or equipment, thereby enhancing overall organizational efficiency.

- One of the main uses of butyl tape rubber is in the construction industry, where it is used for sealing joints and seams in buildings and structures. The tape is applied to the joints between different building materials, such as metal panels, roofing materials, and windows, to create a watertight seal that prevents leaks and moisture intrusion. Butyl tape rubber is also commonly used in the automotive industry, where it is used for sealing and bonding applications in vehicles.

- The appliance industry also benefits greatly from adhesive rubber seal strips

TAPE IS YOUR TRUSTED SOURCE FOR SINGLE COATED TAPES

Creating a high-performance control box means knowing the ins and outs of what you need for your specific application, as well as general best practices of control box design. In this article, we’ll discuss the many types of control boxes used in applications across industries.

One of the standout features of Flex Tape is its ability to conform to irregular surfaces. Whether you're dealing with a smooth surface or something more textured, Flex Tape adheres effectively, ensuring a tight seal. Additionally, its waterproof properties mean that it can be used in wet conditions, making it suitable for both plumbing emergencies and outdoor repairs.

insulation cotton tape. Its gentle nature makes it suitable for sensitive skin, and the cotton material promotes air circulation, aiding in injury recovery. Furthermore, its insulating properties can help regulate body temperature during rehabilitation processes.

insulation cotton tape. Its gentle nature makes it suitable for sensitive skin, and the cotton material promotes air circulation, aiding in injury recovery. Furthermore, its insulating properties can help regulate body temperature during rehabilitation processes.Self-amalgamating tape is very similar to silicone tape, because it bonds to itself when it is stretched. It doesn’t contain any adhesive or gum to create a seal like most tapes. It is made of ethylene propylene rubber and needs to be lapped over itself to work.

The rubber strip is typically made from durable and flexible materials such as silicone or EPDM rubber. These materials are resistant to wear and tear, making them long-lasting and effective at sealing out unwanted elements. The strip is attached to the bottom of the door using adhesive or screws, creating a barrier that blocks out drafts and noise.

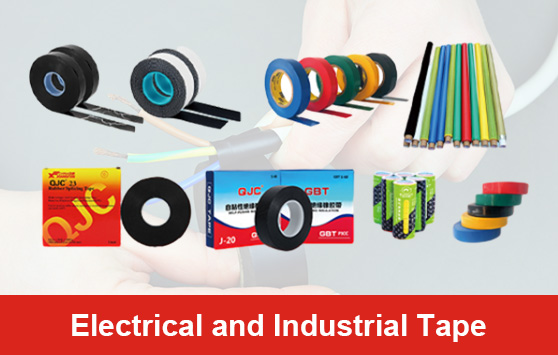

The Benefits of PVC Electrical Insulation Tape

In general, though, most types of electrical tape will start to show signs of degradation at around 70°C.

Silicone tape is also fast and easy to apply, and remove. It leaves no sticky residue, so it saves you time cleaning.