In the realm of manufacturing, the demand for durable and versatile packaging solutions has seen significant growth, particularly in industries such as agriculture, construction, and food processing. One of the most pivotal innovations in this area is the woven sack bag sewing machine. This specialized equipment plays an essential role in the production of woven polypropylene and polyethylene sacks, which are widely used for packing grains, fertilizers, and various bulk materials.

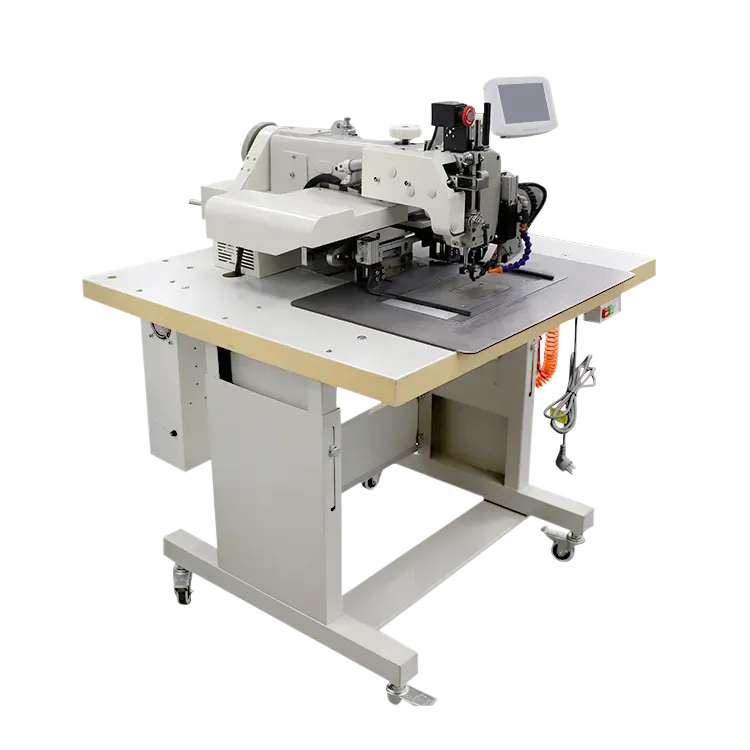

One of the most compelling advantages of CNC upholstery sewing machines is their efficiency. Traditional sewing methods often require multiple operators to gather, cut, and sew fabric pieces together. In contrast, a CNC machine can perform these tasks in a streamlined workflow. This leads to a significant reduction in labor costs and production time, ultimately allowing manufacturers to meet increasing consumer demands without compromising on quality.