3. Durability and Build Quality The materials and construction of the machine can also affect its price. Professional-grade machines constructed with metal components are often more expensive but are built to withstand high-volume use in a commercial setting.

5. Versatility These machines can accommodate various bag sizes and types, making them suitable for a range of products, from small retail items to bulk packaging for industrial use.

Tips for Sewing Vinyl

- One of the key features of a heavy-duty mechanical sewing machine is its strong motor. This motor is capable of generating high-speed stitching, allowing for quick and efficient sewing. Heavy-duty machines also often come with a variety of stitch options and adjustable tension settings, giving users greater control over their stitching projects.

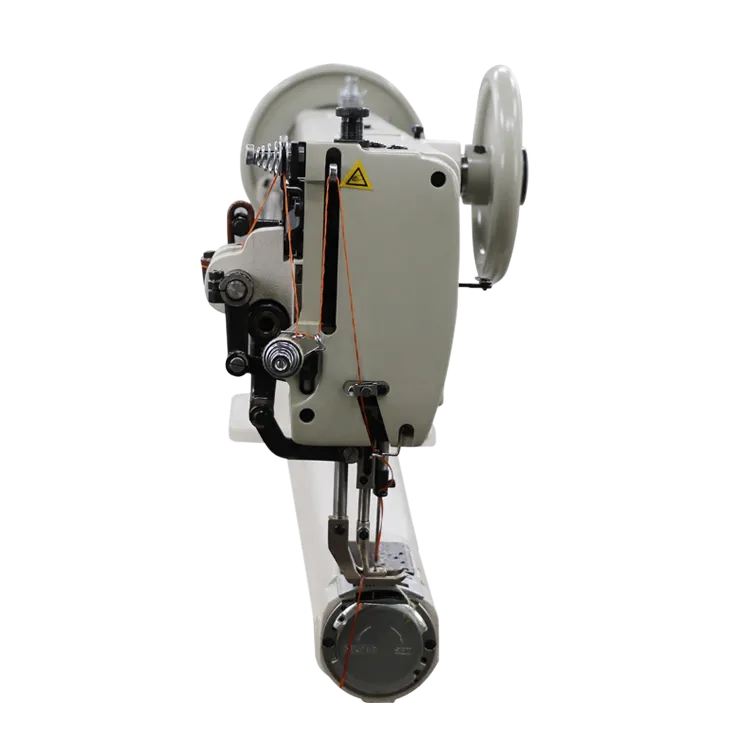

In the realm of industrial packaging, Flexible Intermediate Bulk Containers (FIBCs), commonly known as big bags, are essential for transporting bulk materials. The manufacturing of FIBCs involves various processes, among which sewing is critical to ensure the strength and reliability of the bags. At the heart of this sewing process lies the FIBC sewing machine head, a complex component that significantly influences the quality of the final product.

Maintenance is another crucial factor to consider when choosing a sewing machine, and fortunately, heavy-duty models are generally low-maintenance. Regularly oiling the machine and keeping it clean can significantly prolong its lifespan, yet the durable construction often means fewer breakdowns compared to their lighter counterparts. Some models even have self-cleaning features that further reduce the time spent on upkeep.

One of the primary advantages of a multi-needle quilting machine is its efficiency. Quilters can save significant time during the stitching process, which is particularly beneficial for those who take on larger projects or work on quilts for sale. The ability to stitch multiple colors in a single pass not only speeds up production but also enhances the overall quality and creativity of the finished product.

multi needle quilting machine

A cylinder arm sewing machine is a specialized type of sewing machine that features a cylindrical arm. This design allows for greater maneuverability around awkwardly shaped items, making it particularly suitable for sewing leather goods like bags, belts, and gloves. In contrast to traditional flatbed sewing machines, which can struggle with bulky or rounded materials, the cylinder arm's unique structure enables craftsmen to work on various shapes with ease and precision.

Moreover, the learning curve associated with long arm sewing is often shorter than one might expect. Many manufacturers offer classes and tutorials, ensuring that anyone can get comfortable with the equipment. The sense of community surrounding long arm quilting is also an attractive factor; resources, forums, and local quilt groups can provide support, sharing techniques and inspiration.

Another factor to consider when choosing upholstery machine needles is the type of stitching you will be doing. Different needles are designed for specific types of stitches, such as straight stitching, zigzag stitching, or decorative stitching. By selecting the appropriate needle for the type of stitching you will be doing, you can achieve professional-looking results with clean and precise lines.

1. Efficiency The ability to sew two lines of stitches at once effectively doubles productivity compared to using a single needle machine. This is especially beneficial for sewing projects that require a significant amount of parallel stitching.

Another advantage is the tactile feedback these machines offer. As craftsmen turn the crank, they develop a sense of connection to their work, allowing them to feel the material they are sewing. This hands-on experience can lead to a higher level of craftsmanship and a greater appreciation for the art of leatherworking. The slow, deliberate pace of hand sewing also encourages mindfulness, allowing artisans to focus on each stitch and detail carefully.

In the realm of sewing technology, compound feed sewing machines play a crucial role in various industries, particularly in the fabric and garment sectors. These sophisticated sewing machines are designed to tackle complex fabric manipulation tasks, making them indispensable for manufacturers looking to enhance productivity, consistency, and quality in their products.

1. Sturdy Build One of the most significant advantages of heavy-duty machines is their solid construction. Often made of metal rather than plastic, these machines can withstand the rigors of intensive sewing projects.

Importance of Quality and Safety

climbing rope sewng machine

4. Robust Build Industrial sergers are built for heavy-duty use, often featuring metal components that withstand the rigors of daily operation in a factory. This durability translates to longer lifespans and reduced maintenance needs.

industrial serger machines

Due to the automated features of the heavy duty sewing machine, you can now make detailed, exquisite decorative stitches on fabrics, either on clothes or on beddings and curtains. The heavy duty sewing machine allows you to work with bigger fabrics with ease because it can be turned on with the control pedal by foot, which means both of your hands are free and able to handle the material.

Benefits of Lock Sewing

In the upholstery industry, needle feed machines are favored for their ability to handle heavy-duty fabrics such as leather and vinyl, allowing upholsterers to create durable and visually appealing products. Additionally, these machines find applications in the automotive sector, where they are used to sew upholstery for car interiors, ensuring that the materials maintain their integrity and aesthetics under various conditions.

Understanding Bulk Bag Sewing Machines

Leather sewing machine belts are usually made of high-quality materials such as rubber or synthetic materials that are designed to withstand the rigors of sewing heavy-duty materials like leather. These belts are responsible for transferring power from the motor to the needle, allowing the machine to sew smoothly and efficiently.

It is essential to choose a suitable sewing machine for the job. Lace is a delicate material that needs to be handled carefully, while denim and leather are thick fabrics that require a more robust machine. The choice of the machine affects accuracy, stitch quality, and flexibility. This shows the importance of choosing the right tool for the job.

Taking care of heavy canvas products ensures their longevity. Most heavy canvas is machine washable, but it's crucial to follow the manufacturer’s care instructions. To maintain the strength and color of the fabric, wash in cold water and avoid bleach. If the item is exposed to harsh outdoor conditions, consider using a fabric protector to repel dirt and water.

4. Cotton-Polyester Blends For those who prefer a more traditional look with some stretch, cotton-polyester blends can be a good option. These blends provide a balance of strength and aesthetics, making them suitable for various crafting projects.

The zigzag stitch, a staple in sewing, expands the possibilities of what you can create. Unlike straight stitches, zigzag stitches can stretch, making them ideal for knit fabrics and for areas that require flexibility, like armholes and waistbands. Additionally, zigzag stitches can be used for decorative purposes and finishing edges to prevent fraying. The ability to switch between zigzag and straight stitches means that the long arm heavy duty zigzag sewing machine can adapt to various sewing techniques, allowing for delicate embellishments or sturdy seams as needed.

How Heavy Duty Sewing Machines Revolutionize Crafting: Tips & Tricks

While overlockers are often associated with commercial sewing, they are also incredibly beneficial for home sewers. An overlocker can elevate a hobbyist’s projects, providing a professional finish that significantly improves the appearance of homemade garments. Many modern overlockers come equipped with user-friendly features that make them accessible to sewists of all skill levels, including color-coded threading guides and adjustable stitch settings.

2. Durability Designed for robust materials, these machines can handle multiple layers of leather without compromising the integrity of the stitch. This durability makes them ideal for heavy-duty projects like saddles, belts, and bags.

Finally, finish the edges to prevent fraying. You might want to add embellishments or personal touches, such as monograms or logos, to make the mats uniquely yours.

As the trend continues, it is crucial for consumers to research and understand their specific needs before making a purchase. Factors such as budget, intended usage, and available features should guide their decision-making process. With the right serger machine, individuals can unlock new creative possibilities and enhance their sewing skills, making the investment worthwhile.

One notable aspect of climbing rope sewing machines is their ability to perform multiple stitching types. These include zigzag, straight, bar-tack, and backstitch, which provide additional reinforcement at critical stress points. The precision of the stitching is vital; a well-sewn climbing rope end can be the difference between safety and disaster for a climber. These machines also often come with adjustable speed controls to ensure that each stitch is executed with utmost care and accuracy, reflecting the high standards of quality required in the climbing industry.

1. Automation and Efficiency

Enhanced Precision and Control

- Needle Size Match your thread with the appropriate needle size. Using a thicker thread requires a larger needle to ensure that the fabric and thread work together effectively without damaging the material.