...

2025-08-16 05:03

1474

...

2025-08-16 05:01

2367

...

2025-08-16 04:54

2173

...

2025-08-16 04:33

700

...

2025-08-16 04:03

2213

...

2025-08-16 03:46

1272

...

2025-08-16 02:57

1609

...

2025-08-16 02:47

1952

...

2025-08-16 02:40

356

...

2025-08-16 02:28

2212

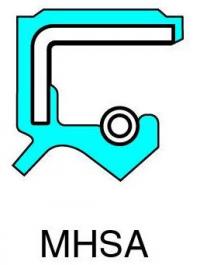

Rubber type

- Regular maintenance and inspection of oil seals are also critical to ensuring their continued effectiveness. This includes checking for signs of wear or damage, such as cracks or tears, and replacing the seal as necessary. Failure to do so can lead to leaks and other issues that can cause significant damage to the machine and its components.

- An oil seal, at its core, serves as a barrier, preventing the leakage of lubricants while also keeping contaminants like dust and debris from entering mechanical systems. The 35x72x10 dimensions denote the size of the seal, with '35' indicating the inner diameter, '72' representing the outer diameter, and '10%' being the lip thickness. The '20' typically refers to the oil seal's material composition or specific properties, which could denote a certain percentage of an additive or material blend.

What are Oil Seals?

Iridium spark plugs have gained popularity in the automotive industry due to their exceptional durability, high melting point, and superior conductivity. These qualities make them an ideal choice for modern motor vehicles, offering enhanced ignition performance, fuel efficiency, and longevity compared to traditional spark plug materials. Iridium spark plugs are designed to deliver consistent and reliable ignition, contributing to improved engine performance and reduced emissions in motor vehicles.