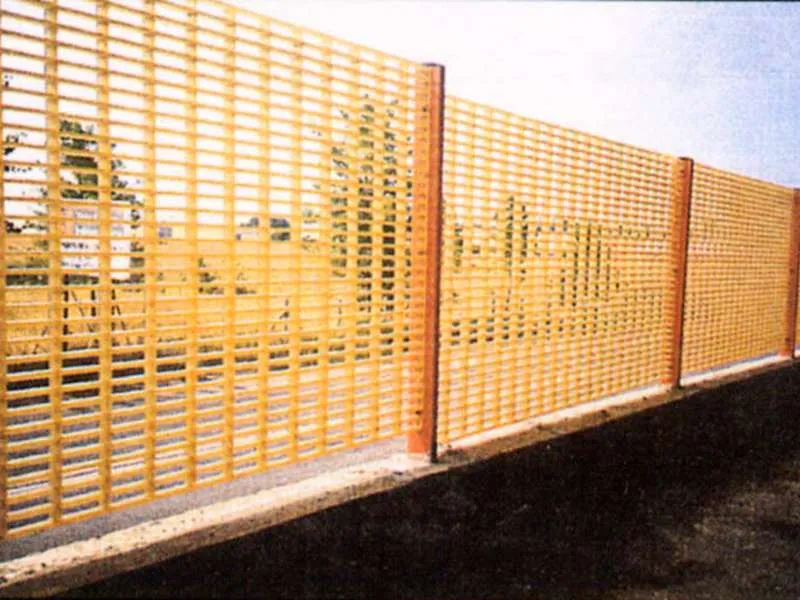

molded frp gratings are manufactured in a one piece construction which results in a bi-directionally strong product. This allows openings for piping or cables in the grating of up to 10” without any additional support required (may vary depending on grating depth and location of opening). During the molded manufacturing process, the continuous fiberglass rovings are completely covered in a high percentage of resin, 65% by volume. With this high resin content, molded gratings are the most chemically resistant gratings offered and are often used in caustic chemical environments without hesitation.

- A marble drill bit is a specialized cutting tool specifically designed to perforate through the hard and dense surface of marble. Unlike regular drill bits that might struggle or damage the marble, these bits are engineered with precision to deliver clean, accurate, and chip-free holes. They typically feature tungsten carbide tips or diamond-coated surfaces, materials known for their exceptional hardness and resistance to wear, ensuring a smooth and efficient drilling process.

- Moreover, the thread button bit is engineered for high-speed drilling, significantly reducing production time and increasing productivity

Another significant benefit of using FRP grating is that it is cost-effective compared to other types of flooring or structural supports. Its minimal maintenance requirements mean that there are fewer costs associated with keeping it in good condition over time. This includes occasional cleaning with soap and water or an approved cleaner if needed. Repairs or replacements are very rarely required. This makes fiberglass grating an attractive option for anyone looking for an affordable yet reliable solution for their project needs.

- Yet, operating a jack hammer demands respect and caution. It is a reminder that power, whether physical or metaphorical, should always be handled responsibly. Just as the operator must wear protective gear, we must safeguard ourselves against the potential harm that can come with unchecked ambition.

- Button bits, when cemented with carbide, offer several advantages over traditional steel bits. Their superior hardness enables them to maintain sharp edges for longer periods, reducing the frequency of bit replacements and thereby increasing overall productivity. Additionally, their resistance to corrosion and high temperatures extends their service life even in harsh drilling environments.

- 6. Drill Weight The weight of the drill affects how easy it is to maneuver. Lighter drills are more portable, while heavier drills provide more stability and power.

- Additionally, fiberglass products find their way into safety gear such as protective clothing and helmets for workers. Their lightweight nature coupled with heat and flame-resistant properties make them ideal for personal protective equipment (PPE), ensuring worker safety in the hazardous steelmaking environment.

- The heavy-duty jack hammer is designed to deliver high-impact blows with its pneumatic or electric power source. It consists of a large piston that strikes the drill bit at high speed, breaking up the material underneath. The force generated by the jack hammer is immense, allowing it to penetrate even the toughest surfaces with ease.

They come in various designs, including step ladders, extension ladders, and platform ladders, catering to different height requirements and tasks They come in various designs, including step ladders, extension ladders, and platform ladders, catering to different height requirements and tasks

They come in various designs, including step ladders, extension ladders, and platform ladders, catering to different height requirements and tasks They come in various designs, including step ladders, extension ladders, and platform ladders, catering to different height requirements and tasks

These bits are designed to create clean and precise boreholes, reducing the need for additional reaming or cleaning of the hole These bits are designed to create clean and precise boreholes, reducing the need for additional reaming or cleaning of the hole

These bits are designed to create clean and precise boreholes, reducing the need for additional reaming or cleaning of the hole These bits are designed to create clean and precise boreholes, reducing the need for additional reaming or cleaning of the hole Its open-grid design allows for water and debris passage, ensuring a safe walking surface Its open-grid design allows for water and debris passage, ensuring a safe walking surface

Its open-grid design allows for water and debris passage, ensuring a safe walking surface Its open-grid design allows for water and debris passage, ensuring a safe walking surface

For waste management facilities, these fittings provide a reliable solution for handling hazardous waste without the fear of leakage or structural degradation For waste management facilities, these fittings provide a reliable solution for handling hazardous waste without the fear of leakage or structural degradation

For waste management facilities, these fittings provide a reliable solution for handling hazardous waste without the fear of leakage or structural degradation For waste management facilities, these fittings provide a reliable solution for handling hazardous waste without the fear of leakage or structural degradation