The Importance of Red and White Floor Marking Tape

Fire-resistant electrical tape is typically made from durable materials such as PVC (polyvinyl chloride), which can endure higher temperatures than standard tapes. These tapes are coated with flame-retardant compounds that significantly reduce the risk of ignition when exposed to heat or flames. Some products may also have a backing made of fiberglass or other inherently flame-resistant materials, adding an extra layer of protection.

In fact, PVC has a very high ignition temperature, meaning it takes a lot of heat to actually set it on fire.

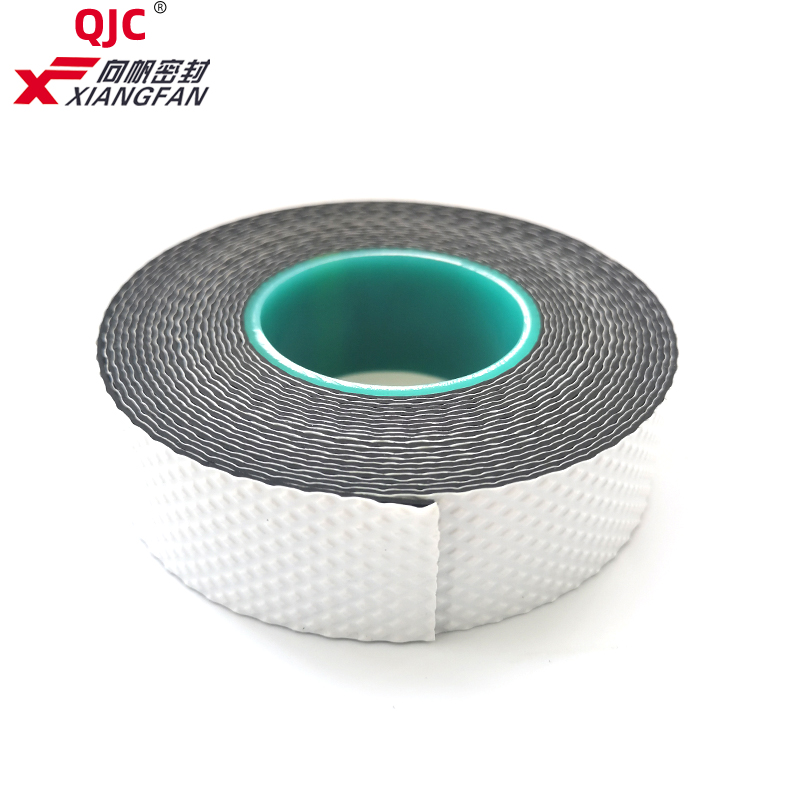

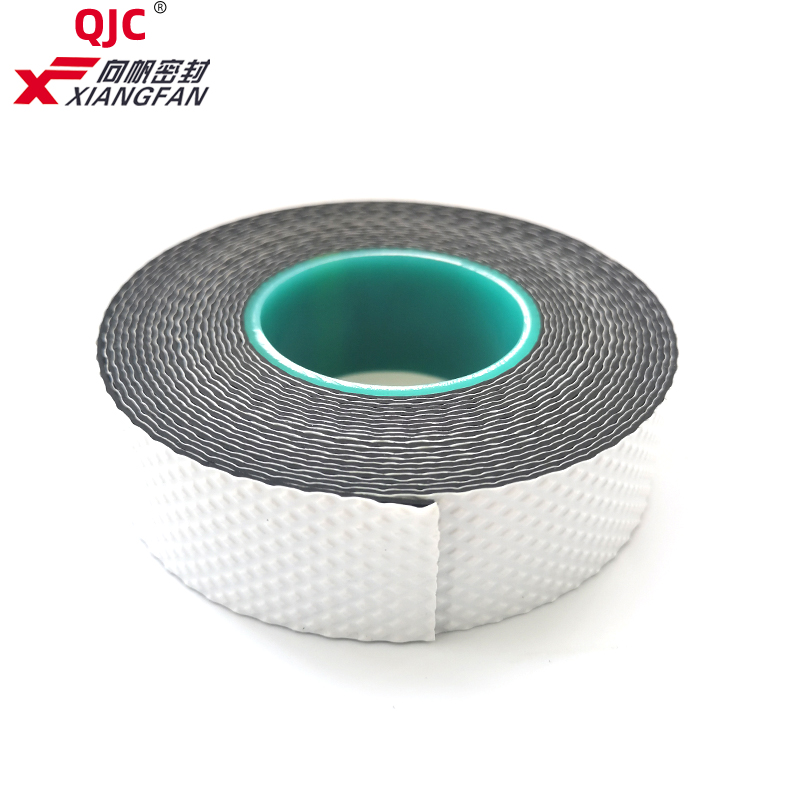

High voltage self-fusing rubber tape is widely used in various industries, including

4. Wide Temperature Range

Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements

Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements butyl rope caulk. Whether you're dealing with a leaky roof, a drafty window, or a,butyl rope caulk is the solution you need.

butyl rope caulk. Whether you're dealing with a leaky roof, a drafty window, or a,butyl rope caulk is the solution you need.Dielectric Strength: 25 kV/mm

3. Peel and stick.Butyl sealant tape usually comes with a protective backing to prevent it from sticking to itself during storage and handling. Carefully peel off the backing to expose the adhesive side of the tape. Position the adhesive side of the tape on the surface, and carefully align it with the area to be sealed.

Pure acrylics have a lower tack (“stickyness when dry” for the layman) and less adhesion on hard-to-bond plastics such as high- and low-density polyethylene (HDPE & LDPE) and polypropylene (PP) than modified acrylic or rubber adhesives. Pure acrylic adhesives are mainly used on tapes whose applications are bonding, sealing or surface protection.

Checking that it meets these standards is crucial when selecting a control box. It’s not just about regulatory compliance; it’s about ensuring the longevity and reliability of your electrical systems.

1. Electrical Projects Red insulation tape is widely used in various electrical projects to insulate wire connections, ensuring safety and functionality. Electricians often use it to mark hot wires in installations, providing a clear visual indication of which wires carry live electricity.

It can be easily cleaned with soap and water, and does not require any special cleaning agents It can be easily cleaned with soap and water, and does not require any special cleaning agents

It can be easily cleaned with soap and water, and does not require any special cleaning agents It can be easily cleaned with soap and water, and does not require any special cleaning agents pvc floor tape. This makes it a low-maintenance option that can save time and money in the long run.

pvc floor tape. This makes it a low-maintenance option that can save time and money in the long run.PVC electrical tape Vs vinyl electrical tape – what’s the difference?

Its waterproof barrier not only stops leaks instantly but also prevents future damage by blocking water penetration Its waterproof barrier not only stops leaks instantly but also prevents future damage by blocking water penetration

Its waterproof barrier not only stops leaks instantly but also prevents future damage by blocking water penetration Its waterproof barrier not only stops leaks instantly but also prevents future damage by blocking water penetration gray flex seal tape.

gray flex seal tape.The Versatility of Black Flex Tape