2.What strategies can be employed to ensure a warehouse design is future-proof?

In conclusion, hanger air is a critical aspect of aviation maintenance that cannot be overlooked. Ensuring a controlled environment with clean, temperature-regulated air contributes to the safety and efficiency of maintenance operations. It protects the aircraft's integrity and safeguards the health of personnel working within the facility. By prioritizing hanger air quality, the aviation industry can enhance maintenance practices, address environmental concerns, and ultimately ensure the safety of passengers and crew.

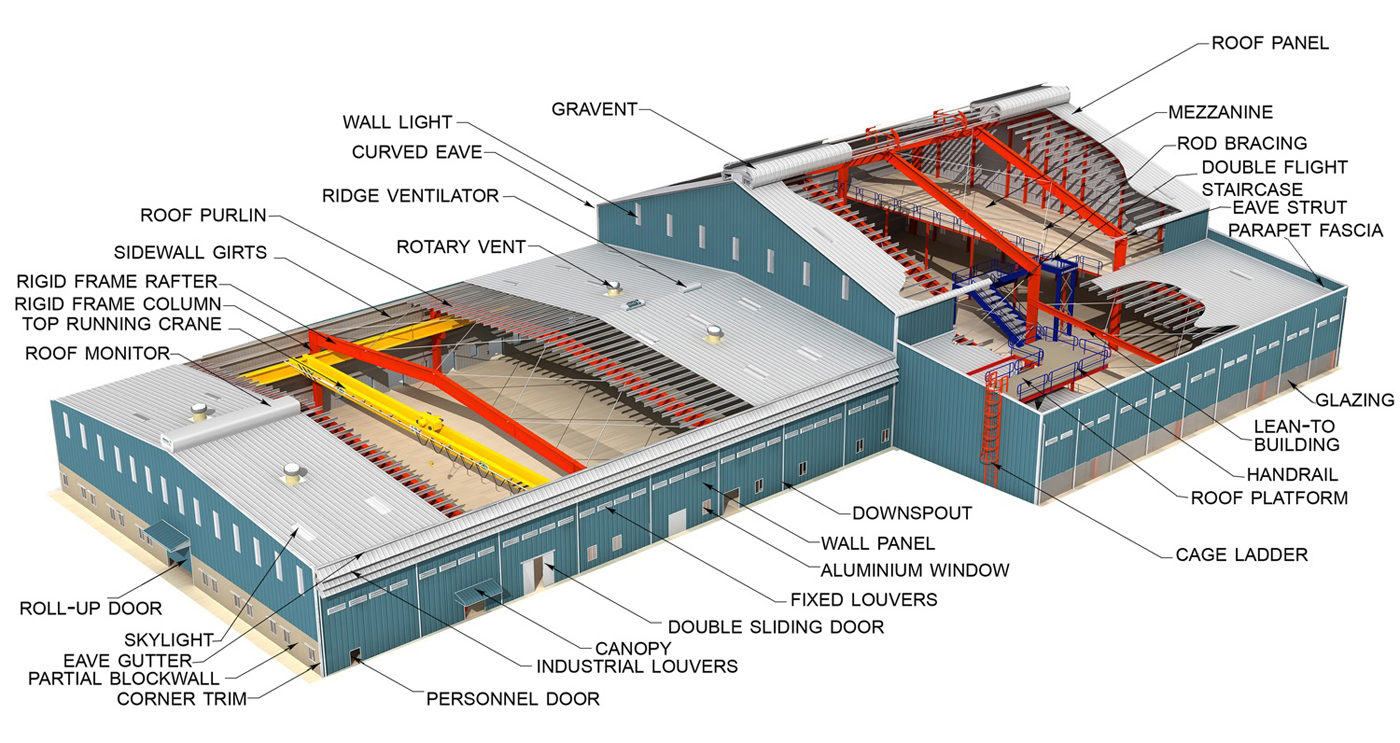

Steel structure warehouse buildings usually consist of steel beams, columns, steel trusses, and other components.

The various components or parts are connected by welding, bolting, or rivets.

1. Main structure

The main structure includes steel columns and beams, which are primary load-bearing structures. It is usually processed from steel plate or section steel to bear the entire building itself and external loads. The main structure adopts Q345B steel.

2. Substructure

Made of thin-walled steel, such as purlins, wall girts, and bracing. The secondary structure helps the main structure and transfers the main structure’s load to the foundation to stabilize the entire building.

3. Roof and walls

The roof and wall adopt corrugated single color sheets and sandwich panels, which overlap each other during the installation process so that the building forms a closed structure.

4. Bolt

Used to fix various components. Bolt connection can reduce on-site welding, making the installation of steel structure easier and faster.

Versatility and Design

3. Local Building Codes and Regulations Prices can vary based on location due to local building codes and zoning regulations. Areas with stricter codes may require additional permits or inspections, which can add to the overall cost. It’s essential to check these regulations before making a purchase to avoid unexpected expenses later on.

prefab metal buildings prices

6. Additional Features and Customization

Energy Efficiency

Custom metal buildings are a somewhat heftier investment. But with a building designed to match your company’s services and policies, it brings a touch of competitive pricing.

An advantage of a metal garage with an office is the opportunity to integrate eco-friendly solutions. Installing solar panels on the roof can reduce energy costs, providing power for both the office and garage operations. Additionally, choosing energy-efficient lighting and heating solutions not only minimizes the carbon footprint but also contributes to long-term savings on utility bills.

In today's fast-paced industrial environment, the demand for efficient, durable, and adaptable structures has never been higher. Steel construction has emerged as a preferred choice for warehouses, providing a range of benefits that cater to the needs of modern businesses. This article explores the significance of steel construction in warehousing and its impact on operational efficiency, safety, cost-effectiveness, and sustainability.

Steel Structure Buildings The Future of Warehousing

Another critical aspect of hanger air management is temperature and humidity control

. Different aircraft systems have specific operational ranges concerning temperature and humidity. Exposure to extreme conditions may lead to corrosion, material fatigue, and other degradation processes that could adversely affect an aircraft’s performance. Therefore, maintaining an optimal temperature and humidity level within hangers is essential for prolonging the lifespan of aircraft components. Regular monitoring of these environmental conditions ensures that maintenance crews can work efficiently and effectively, thus leading to better repair outcomes.hanger air

Furthermore, industrial buildings have a significant impact on regional development and urban planning. Governments and urban planners often prioritize the establishment of industrial zones, recognizing their potential to invigorate local economies. By designating specific areas for industrial use, cities can streamline infrastructural development, such as road networks and utilities, which not only benefit industrial operations but also enhance the quality of life for residents in surrounding areas.

Another essential benefit of steel structure warehouses is the speed of construction. Steel sections can be pre-fabricated, meaning they are manufactured off-site and then transported to the construction location. This method significantly reduces the construction time compared to traditional building methods, leading to quicker project completion, and allowing businesses to commence operations without delay. Time is often a critical factor in the logistics and manufacturing industries, and steel structures meet this need effectively.

steel structure building warehouse

In recent years, prefabricated metal buildings have gained immense popularity across various industries, including agriculture, commercial enterprises, and individual homeowners. One of the most significant factors driving this trend is the cost-effectiveness of these structures. This article will explore the pricing of prefabricated metal buildings, the factors influencing their costs, and potential savings for buyers.

Insulating a metal garage can significantly enhance its functionality, making it a comfortable space for various uses, from a workshop to a home gym or even an office. Metal garages, while durable and low-maintenance, are notorious for being poor insulators. They can become extremely hot in the summer and freezing cold in the winter. In this article, we’ll explore the importance of insulation, the best materials to use, and the installation process involved.

The metal workshop with living quarters is more than just a physical space; it represents an innovative approach to the artist's lifestyle. It harmonizes work and home, promotes creative exploration, fosters community, and embraces sustainability. As the demand for unique artisan products grows, these workshops stand at the forefront, offering a fulfilling and integrated way to pursue one’s passion for metalworking.

Flexibility in design is a hallmark of premanufactured steel buildings. They can be customized to meet the specific needs of various industries, from warehouses and industrial facilities to retail spaces and office buildings. The versatility of steel allows for larger spans and open floor plans, providing ample space for operations and future expansions. This flexibility ensures that businesses can adapt their facilities to changing demands without having to undertake significant renovations.

premanufactured steel buildings

6. A Smaller Ecological Footprint

Durability and Longevity

The Rise of Prefabricated Building Factories

Versatility in Design and Function

large metal storage sheds

Sustainability

Implementing preventative maintenance measures, such as surface treatments and system upgrades, can extend the life of the warehouse, preventing degradation and ensuring continued compliance with safety standards.

In the ever-evolving field of agriculture, the efficiency of farm operations can significantly impact productivity and profitability. One crucial aspect often overlooked is the provision and maintenance of proper farm equipment buildings. These structures serve as the backbone of modern farming, ensuring that machinery and tools are housed, organized, and maintained effectively.

Large metal storage sheds are available in various sizes and designs, making it easy to find the perfect fit for your space. Whether you need a small shed for garden tools or an expansive structure for larger equipment, options are plentiful. Furthermore, these sheds can often be customized to include shelving, workbenches, and overhead storage, allowing you to maximize the use of space and organize your tools efficiently.

large metal storage sheds

Sustainability is also a growing consideration in the construction of farm equipment buildings. Many farmers are opting for environmentally friendly materials and practices that reduce their carbon footprint. For instance, solar panels can be integrated into the building’s design, providing renewable energy for lighting and machinery. Additionally, incorporating rainwater harvesting systems can provide water for cleaning equipment or irrigating nearby crops.

2. Materials The type and quality of steel used in construction are key determinants of the overall expense. Higher-grade steel may incur additional costs but often provides greater strength and longevity, leading to savings in maintenance and repair over time. Other materials, including insulation, windows, and roofing systems, also contribute to the total expenditure.

The Evolution and Benefits of Metal Building Manufacturing

With the increasing emphasis on environmental sustainability, many manufacturers are gravitating toward sustainable factory designs. These buildings incorporate features such as solar panels, rainwater harvesting systems, and energy-efficient insulation. Sustainable factories aim to reduce the ecological footprint of operations while promoting a greener manufacturing process. Such designs not only appeal to environmentally conscious consumers but can also result in long-term cost savings through reduced energy expenses.

Understanding Load Requirements

2. Foam Board Insulation This rigid insulation board offers high insulation value with a thinner profile. It can be applied directly to the metal walls and provides a solid barrier against moisture.

insulating a metal garage