...

2025-08-14 05:44

2002

...

2025-08-14 05:32

543

...

2025-08-14 05:24

1257

...

2025-08-14 05:19

1191

...

2025-08-14 04:14

250

...

2025-08-14 04:09

2296

...

2025-08-14 03:52

490

...

2025-08-14 03:40

70

...

2025-08-14 03:28

546

...

2025-08-14 03:22

1710

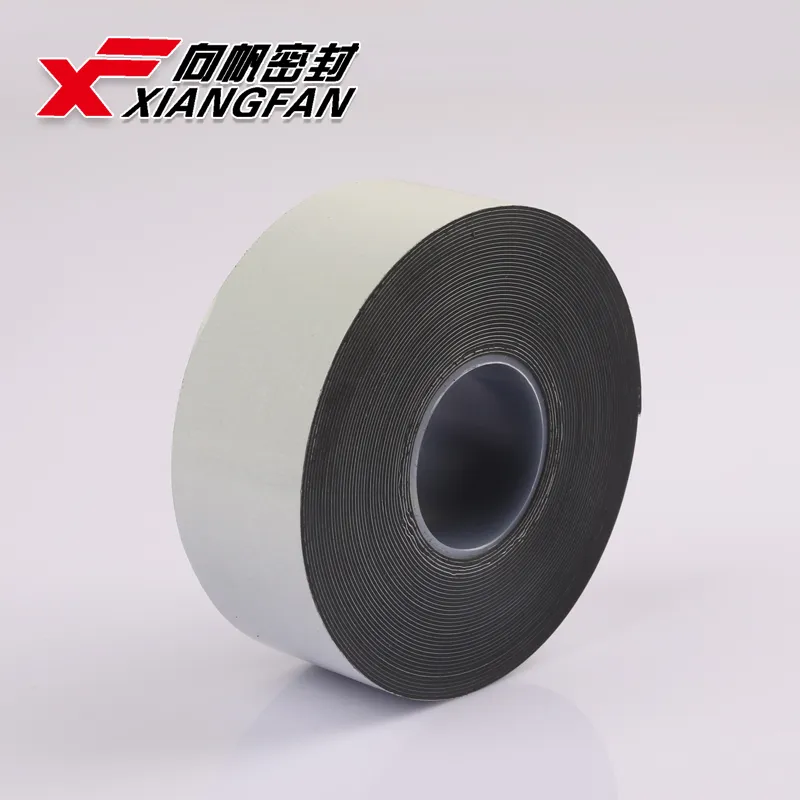

Their tapes not only provide outstanding sealing capabilities but also contribute to environmental conservation through their recyclable materials Their tapes not only provide outstanding sealing capabilities but also contribute to environmental conservation through their recyclable materials

Their tapes not only provide outstanding sealing capabilities but also contribute to environmental conservation through their recyclable materials Their tapes not only provide outstanding sealing capabilities but also contribute to environmental conservation through their recyclable materials