Knock sensors detect engine knocking or pinging, a phenomenon caused by premature combustion. By monitoring these vibrations, the ECU can adjust ignition timing to prevent knocking, enhancing engine performance and longevity.

Aluminum Fencing

2. Bottom-Mount Rollers These rollers are installed at the base of the door and support the weight of the door while allowing it to glide smoothly along the track. They are crucial for maintaining balance.

One of the most common uses of decorative cast iron elements is in building facades. From ornate column capitals to elaborate window grilles, these elements can transform a plain building into a work of art. The intricate patterns and designs add a touch of sophistication and grandeur to any structure, making it stand out from the rest.

- Moreover, the versatility of wrought iron makes it suitable for various design styles. It can be sleek and minimalist for contemporary spaces or intricately detailed for a more classical or vintage look. Its ability to be bent, twisted, and welded allows for endless design possibilities, from geometric patterns to elaborate floral motifs.

4. Adjustable Wheels Some sliding door wheels are designed with adjustability features, allowing for height modifications to ensure optimal alignment with tracks. This is crucial for maintaining a smooth operation over time.

Steel pull handles are available in a wide array of designs, finishes, and sizes, allowing for customization to suit various architectural styles. From sleek, modern designs to more ornate, classic styles, there is a steel pull handle for every aesthetic. Various finishes, including brushed, polished, and powder-coated options, provide further opportunities for customization while also offering additional corrosion resistance. This versatility allows for seamless integration with diverse design themes, whether contemporary, industrial, or traditional.

steel door pull handles

Domestic Charm

Think of the cast iron frying pan you probably have in your kitchen. Unlike a stainless steel saute pan which likely has a handle made of a separate piece that had to be attached to the main body of the pan, your cast iron is all one continuous piece that was formed together in a mold.

Should wrought iron be given a coat of paint?

The biggest difference between these two types of fences is the material they are made from.

While it does require more maintenance to prevent rust and corrosion, the effort is often considered worthwhile for the unparalleled elegance and robustness it brings to your property.

Step-by-Step Guide to Adjusting Sliding Door Rollers

5. Finials

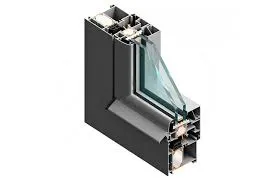

The aluminum alloy profiles are made of new thermal insulation materials. A cold and hot bridge is formed between the inner and outer profiles to minimize the thermal conductivity of aluminum alloy and achieve good thermal and sound insulation effects.

What most people are after when they want a wrought iron fence is a certain appearance, like the distinctive look of wrought iron fencing in front of a Victorian house. To explain this look, you need to know something about ironwork. To start with, there are two main types of iron. Cast iron involves pouring the iron into a mold while it’s molten and allowing it to cool into a distinctive shape. Wrought (worked) iron is iron that has been heated until red hot, then pulled, twisted, or extruded into shape. These two processes used to be used to produce a variety of distinctive features in fences.

4. Adjustment Sometimes, the alignment of the rollers may need adjustment. If a window is difficult to open or closes unevenly, consult a professional to make the necessary adjustments.