In 1845, a surgeon named Dr. Horace Day made the first crude surgical tape by combining India rubber, pine gum, turpentine, litharge (a yellow lead oxide), and turpentine extract of cayenne pepper and applying that mixture to strips of fabric. It was the first “rubber-based” adhesive and Dr. Day used it in his practice as a surgical plaster. Larger scale manufacturing of similar medical tapes began in 1874 by Robert Wood Johnson and George Seaburg in East Orange, NJ. That company would soon become the Johnson & Johnson Company we know today. Later in 1921, Earle Dickson who bought cotton for Johnson & Johnson noticed that the surgical tape kept falling off his wife Josephine’s fingers after cutting them in the kitchen. He fixed a piece of gauze to some cloth backed tape and the first Band-Aid ® was invented. It took almost 75 years from Dr. Day’s first crude tape until the early 1920’s when the first industrial tape application appeared. The application was electrical tape (although the adhesive was more of a cohesive film than the electrical tape we know today) to prevent wires from shorting. The second major industrial tape application was a result of the rise of the American automobile in the 1920’s. Two-toned automobiles were becoming popular and automakers needed a way to produce clean, sharp paint lines while using the new automatic paint spray gun. They started using the surgical tape that was available but the paint wicked through the cloth backing and caused defective paint jobs. Richard Drew, an engineer at Minnesota Mining and Manufacturing (3M) happened to be at a local body shop testing their WetorDry® brand sandpaper in 1925 and he saw the workers struggling to get clean paint lines. He went back to his lab and created a 2-inch wide crimp backed paper tape that became the first “masking tape” for painting. Jumping ahead to 1942 and World War II, Johnson & Johnson developed duct tape to seal canisters and repair equipment for the military. The tape was a basically a polyethylene coated cloth tape with good “quick stick” properties that made it easy to use in the field for emergency repairs. The world never looked back and duct tape can be found in almost any home or toolbox.

- In warehouses, floor tape serves as an efficient tool for inventory management. It can be used to mark storage locations, streamline material handling, and optimize space utilization. The clear division helps to maintain an organized workflow, enhancing productivity and minimizing potential accidents.

- In conclusion, butyl rubber tape is a valuable product that plays a crucial role in many industries in China. Its durability, adhesion properties, and easy application make it a preferred choice for sealing, waterproofing, and insulation applications. Whether used in construction, automotive, or manufacturing, butyl rubber tape is an essential tool for achieving airtight and watertight seals. As technology continues to advance, the demand for butyl rubber tape in China is expected to grow, further solidifying its reputation as a reliable and versatile product.

- In addition to their energy-saving benefits, weatherstrip seals also protect the integrity of the building structure

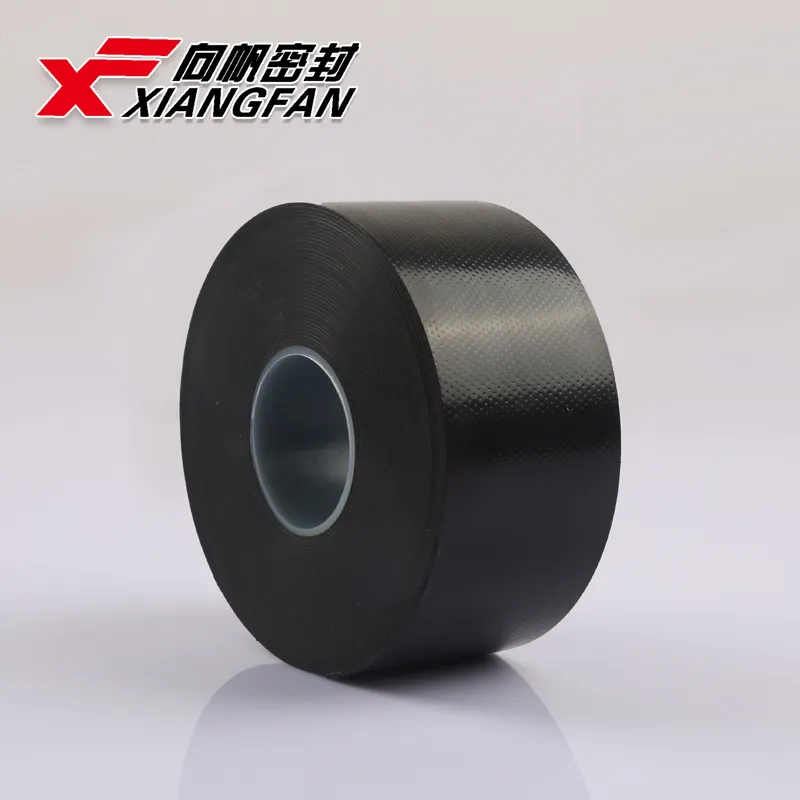

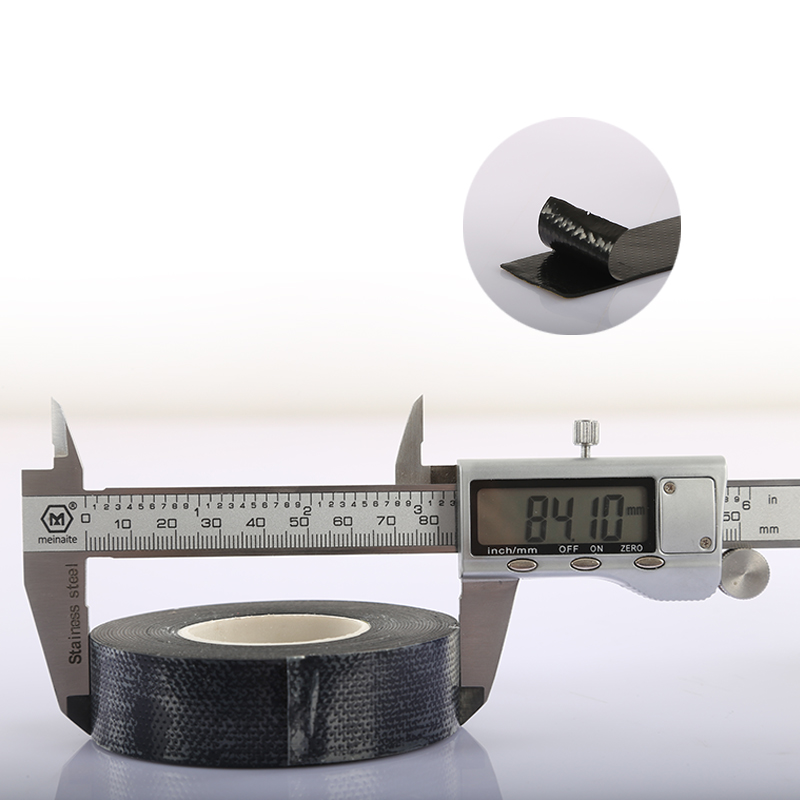

self vulcanizing tape. It is employed to repair and protect pipes, tanks, and other structures from corrosion and damage. The tape's ability to adhere tightly to various surfaces, even in the presence of moisture or extreme temperatures, makes it an invaluable asset for contractors and maintenance personnel.

self vulcanizing tape. It is employed to repair and protect pipes, tanks, and other structures from corrosion and damage. The tape's ability to adhere tightly to various surfaces, even in the presence of moisture or extreme temperatures, makes it an invaluable asset for contractors and maintenance personnel.The chemical resistance of silicone insulation tape is another noteworthy feature. It is resistant to moisture, UV rays, and various chemicals, ensuring that it performs reliably in diverse environmental conditions. This makes it suitable for both indoor and outdoor applications, from sealing around electrical conduits to insulating components in marine and automotive settings.

silicone insulation tape

PVC insulation tape uses

The unique properties of butyl rubber make it an ideal material for waterproofing applications. Butyl rubber is known for its excellent resistance to water, chemicals, and UV rays, making it highly durable and long-lasting. It also has a high level of elasticity, allowing it to flex and move with the underlying surface without losing its waterproofing capabilities. This flexibility ensures that butyl rubber waterproofing remains effective even in changing weather conditions or structural movement.

For specialized projects, you may require custom solutions. A reputable supplier should have the capability to provide customized butyl rubber tape solutions tailored to your needs. Additionally, technical support is crucial, especially for complex applications. Suppliers who offer expert guidance on product selection and application can help ensure that you achieve optimal results.

One of the most significant advantages of butyl rubber is its low permeability to air and other gases. This attribute is particularly valuable in applications where maintaining an airtight seal is critical. Additionally, butyl rubber is resistant to UV radiation, oxidation, and aging, allowing it to withstand harsh environmental conditions without degrading.

4. Electrical Insulation The primary function of red insulation tape is to provide electrical insulation. It can effectively cover exposed wires, preventing accidental contact and short circuits.

red insulation tape

5. Allow the tape to cure Once wrapped, let the tape sit for a few minutes to allow it to cure and create a strong bond. Depending on the type of tape, it may take anywhere from a few minutes to a few hours to fully cure.

Wrap and Stretch: Begin wrapping the tape around the object or area that needs repair. Stretch it slightly as you wrap to activate the self-fusing properties.