Aluminum alloys and resin (materials with a large difference between the linear expansion coefficients) demand sufficient consideration (as there is a risk of failure due to the increased clearance with the oil seal at high temperatures).

Oil Seal Overview

Their non-conductive properties make them perfect for this application, preventing short circuits and ensuring safety Their non-conductive properties make them perfect for this application, preventing short circuits and ensuring safety

Their non-conductive properties make them perfect for this application, preventing short circuits and ensuring safety Their non-conductive properties make them perfect for this application, preventing short circuits and ensuring safety square rubber gasket.

square rubber gasket.In conclusion, installing oil seals correctly is an important step in maintaining the performance and efficiency of rotating machinery. By following these steps, you can ensure that your oil seals are installed correctly and will provide a leak-free performance. If you have any questions or concerns about installing oil seals, consult with a professional or refer to the manufacturer's instructions. Proper installation of oil seals can help to extend the life of your machinery, reduce the risk of leaks, and ensure a safe and efficient operation.

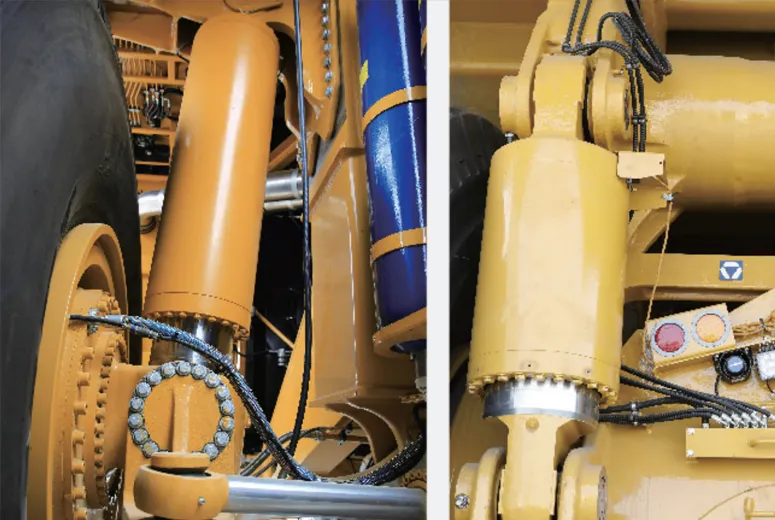

Oil seals are used in many areas around the car.

Figure 6 shows the places where each seal type is used.

l7tc spark plug. By improving fuel efficiency and reducing emissions, this innovative plug helps to mitigate the impact of transportation on the environment. As concerns about climate change continue to grow, the L7TC Spark Plug represents a promising solution for the future of sustainable transportation.

l7tc spark plug. By improving fuel efficiency and reducing emissions, this innovative plug helps to mitigate the impact of transportation on the environment. As concerns about climate change continue to grow, the L7TC Spark Plug represents a promising solution for the future of sustainable transportation.The sealing element makes up the interior of the oil seal, and the materials commonly used are:

Proper preparation is crucial for successful oil seal installation. Ensuring that the seal, shaft, and bore are correctly prepared and aligned prevents seal failure, leakage, and premature wear of the components.

Heat resistance