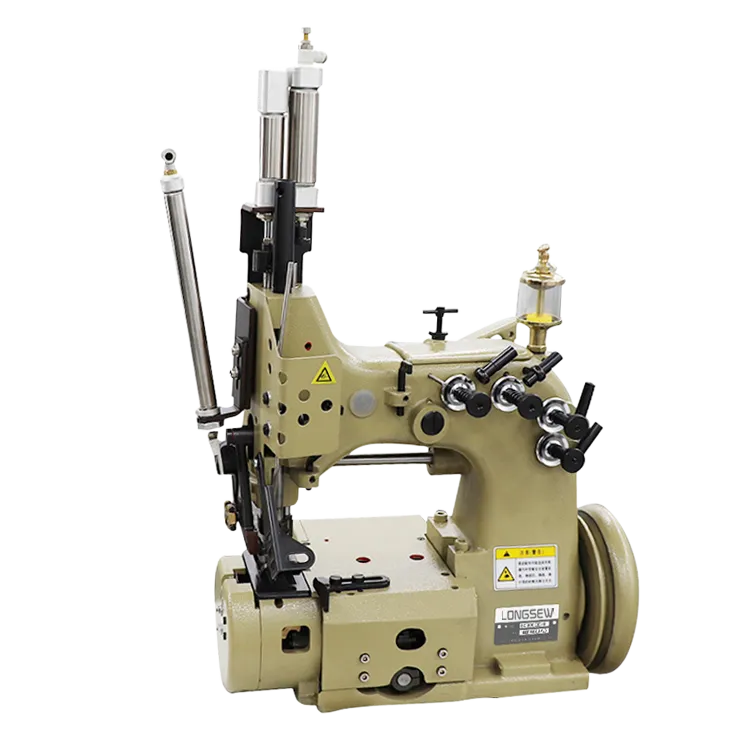

- The jumbo bag lock stitch machine features a robust construction and powerful motor that can handle the demands of industrial production. It is equipped with multiple needles and thread spools, allowing for fast and efficient stitching of the bag panels. The machine also has adjustable settings for stitch length, tension, and speed, giving operators control over the quality of the stitching.

- Single needle stitching is a form of sewing that uses only one needle to create precise and durable stitches. This technique is commonly used in tailoring and textile manufacturing to create high-quality garments and products.

Additionally, consider the machine’s presser feet and needle options. Look for a machine that comes with a range of presser feet designed for heavy duty sewing, such as a walking foot for even feeding of thick materials, a zipper foot for sewing zippers on heavy fabrics, and a leather needle for sewing leather and other tough materials.

Heavy Duty Sewing Needles A Comprehensive Guide

Finally, maintaining your needles is essential. Over time, needles can become dull or bent, affecting their performance. It’s a good practice to replace needles regularly, especially when switching between different types of fabrics or after extended sewing sessions.

In addition to speed and efficiency, sofa upholstery sewing machines contribute to sustainability in the furniture industry. By optimizing the sewing process and minimizing fabric waste through precise cutting and stitching, these machines help reduce the environmental impact associated with furniture production. Moreover, the durability of sofas constructed using these machines means that consumers are more likely to invest in high-quality pieces that last longer, reducing the need for frequent replacements.

One Extreme Heavy Duty Sewing Machine Option

The significance of sewing machine chains extends beyond mere efficiency. They have contributed to the cultural and social shifts within the textile industry. With the ability to mass-produce garments, sewing machine chains have facilitated the rise of the fast fashion industry. This phenomenon has made fashionable clothing accessible to broader audiences, but it has also raised questions about sustainability and ethical labor practices. The ease of production has led to increased demand for cheap, quickly made garments, often at the expense of quality and the well-being of workers in developing countries.

sumo overlock sewing machine. Whether you are working with lightweight fabrics like silk and chiffon or heavier materials like denim and canvas, this machine can handle it all. It can sew a variety of stitches, including overlock, flatlock, and rolled hem, giving you the freedom to experiment and create unique designs.

The Versatility of Long Arm Sewing Machines

In the world of sewing, having the right machinery can make a significant difference in the quality of work produced. Among the various types of sewing machines available, the heavy-duty mechanical sewing machine stands out as a reliable companion for both novice and seasoned seamstresses. This article delves into the features, benefits, and applications of heavy-duty mechanical sewing machines, highlighting why they are an essential tool in any sewing enthusiast’s arsenal.

Final Tips

What to Look for In a Heavy Duty Sewing Machine

Conclusion

Hand Crank Sewing Machine for Leather A Timeless Tool for Craftsmanship

Case Studies Comparing Costs Over Time

heavy duty post bed sewing machine .

According to the U.S. Bureau of Labor Statistics, 116,220 professionals use sewing machines in their work[1]. For the rest of us, we are more likely to use sewing machines for personal use, for hobbies, or for a second job or side hustle. However, you don’t need to be a professional to benefit from a heavy-duty sewing machine's increased speed and longevity. But before spending a small fortune on an industrial-type sewing machine, ask yourself some questions to see if a lower-cost portable sewing machine may be a better choice.

The Essential Role of Jumbo Bag Sewing Machinery in Modern Manufacturing

Conclusion

The first step in creating car mats is selecting the right materials. The most common fabrics include durable rubber, heavy-duty carpet, and even recycled materials for environmentally conscious creators. Rubber mats provide excellent water resistance and easy cleaning, while heavy-duty carpet can add a touch of style and comfort.

1. Walking Foot Machines These machines are ideal for sewing thick leather materials. They feature a walking foot mechanism that keeps multiple layers of leather moving uniformly, preventing any slipping or uneven stitching. This is particularly beneficial for items like bags, belts, and jackets.

industrial machine for sewing leather

One of the key features of holster sewing machines is their heavy-duty construction. These machines are built to handle the thick and tough materials typically used in holster making, including leather and Kydex. The powerful motor and sturdy design allow users to sew through multiple layers of material with ease, ensuring a strong and durable finished product.

For those who frequently work with heavy fabrics like denim, canvas, or leather, the double needle walking foot sewing machine is a game-changer. Traditional machines often struggle to handle bulky materials, leading to skipped stitches and uneven seams. However, the combination of a walking foot and double needles provides the necessary power and stability to navigate these challenging textiles with ease.

The world of sewing is filled with a variety of techniques and methods that elevate the quality and durability of garments. Among these, the double needle coverstitch has emerged as a popular choice for both amateur and professional sewists alike. This technique combines the utility of a sewing machine with the aesthetic appeal of a serger, making it an essential tool in garment construction and finishing.

Conclusion

In the fast-paced world of fashion and apparel, efficiency and precision are paramount. As the demand for high-quality garments continues to grow, the garment industry has turned to technology for solutions. Among these innovations, automatic sewing machines have emerged as game-changers, particularly in shirt manufacturing. These machines represent a significant leap forward in automating the sewing process, offering a myriad of benefits for manufacturers and consumers alike.

Setting Up for Sewing

One of the key features of a compound feed heavy-duty sewing machine is its enhanced feeding mechanism. This type of sewing machine typically has two feed mechanisms – one on the presser foot and one on the needle bar. This dual feed system ensures that the fabric is fed evenly through the machine, preventing slippage, puckering, and uneven stitches. As a result, you can achieve perfectly aligned seams, stitching, and patterns even on thick or hard-to-handle materials.

At its core, leather hand stitching is an intricate process that requires skill, patience, and an understanding of materials. The primary tools involved include needles, waxed thread, and various other hand tools for cutting and preparing the leather. Craftsmen often prefer using high-quality leather, such as vegetable-tanned leather, which not only ages gracefully but also acquires a beautiful patina over time.