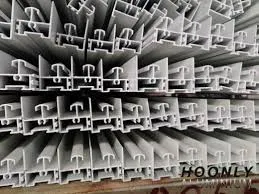

Aluminium extrusion profiles offer several advantages that make them highly sought after in the windows and doors segment. First and foremost, aluminium is lightweight yet robust, making it ideal for constructing large windows and doors without compromising structural integrity. The extrusion process enables the creation of complex profiles with varying cross-sectional shapes, allowing for enhanced functionality and design possibilities.

- When selecting aluminium sliding door rollers, it's important to consider the size and weight of the door you plan to install them on

- When it comes to brands, some well-known manufacturers of sliding window wheels include BMF, Vossen, and Forgiato. These brands offer a wide range of sliding window wheels in various sizes and styles, so you can find a set that perfectly matches your vehicle and budget.

- In addition to their durability, sliding security screen door rollers are also easy to install and maintain. With just a few simple tools and some basic DIY skills, you can replace old or damaged rollers in minutes, ensuring that your security system remains in top condition at all times. Regular lubrication and cleaning can help prolong the life of the rollers and prevent them from getting stuck or jammed.

For materials to be able to serve as constructional support, they need to be durable, stable, and strong, to contribute to a particular building’s structural integrity.

Aluminum profiles are mainly the product of the aluminum extrusion process, where an aluminum billet is passed through a die. The result — varying types of aluminum profiles that have wide uses across residential, industrial, and constructional spaces.

- * Industrial Equipment Cast iron panels are used in the production of industrial equipment, such as boilers, furnaces, and reactors, due to their heat resistance and durability.

- In the realm of home improvement and interior design, aluminium door runners often go unnoticed, yet they play a pivotal role in ensuring the seamless operation of doors. These humble components, though seemingly insignificant, contribute significantly to the functionality and longevity of our daily entryways.

3. Inspect the Rollers Examine the rollers for signs of wear and tear. If they are damaged, they may need to be replaced rather than adjusted. If they appear in good condition, you can proceed with the adjustment.

- Clean the Wheels and Tracks Dust, dirt, and debris can accumulate over time, leading to rolling issues. Regularly clean the wheels and the track with a damp cloth to remove any obstructions.

The ball bearings reduce friction between the rollers and the track, resulting in a silent and effortless sliding motion The ball bearings reduce friction between the rollers and the track, resulting in a silent and effortless sliding motion

The ball bearings reduce friction between the rollers and the track, resulting in a silent and effortless sliding motion The ball bearings reduce friction between the rollers and the track, resulting in a silent and effortless sliding motion ball bearing sliding door rollers. This is especially important for homeowners who want to maintain a peaceful and noise-free environment in their homes.

ball bearing sliding door rollers. This is especially important for homeowners who want to maintain a peaceful and noise-free environment in their homes. Compatibility is key; ensure the wheels you choose are designed to fit your specific door model Compatibility is key; ensure the wheels you choose are designed to fit your specific door model

Compatibility is key; ensure the wheels you choose are designed to fit your specific door model Compatibility is key; ensure the wheels you choose are designed to fit your specific door model replacement roller wheels for sliding screen door. Also, look for wheels with ball bearings, as they offer a smoother roll and reduced friction. The material of the wheel - be it plastic, metal, or a combination - should be durable enough to handle various weather conditions.

replacement roller wheels for sliding screen door. Also, look for wheels with ball bearings, as they offer a smoother roll and reduced friction. The material of the wheel - be it plastic, metal, or a combination - should be durable enough to handle various weather conditions.Firstly, ensure you have the right tools on hand. You'll need a screwdriver (both flathead and Phillips, depending on the door), pliers, replacement rollers, and a measuring tape. Replacement rollers can be found at any hardware store or online, with measurements typically provided to ensure a perfect fit.

While aluminum does have its merits, it just can’t compete with the grandeur and reliability that wrought iron brings to the table. It really only has an edge in the short term cost consideration and maintenance needs.

Furthermore, it easy to strengthen it by heat treatment by placing it at a temperature of at least 320° F for several hours.

The process of extrusion in aluminum usually involves the passage of a solid aluminum billet into a die. This is typically done with the assistance of a high-pressure hydraulic press, or ram, to force the block into the die.

Long term, high-end architecture. Wrought iron holds up to harsh weathering longer than steel. It doesn’t corrode as easily or as quickly. If you want to build an ornate fence that will still be standing about a hundred years from now, choose wrought iron. For example, the legendary Johnston Gate of Harvard University is +100 years old and still stands strong.

Lubricate the window’s moving parts routinely: The hinges and locks of old windows might experience unnecessary wear and tear over time, making them difficult to use and stiffer. Apply a lubricant that contains silicone to the moving elements to avoid this from happening. Simply add a very tiny amount of lubricant to the hinges and locks, and then open and close the door a few times to work the oil into the hinges and locks.

In conclusion, thermal break aluminium profiles represent a significant advancement in building technology, combining aesthetics with performance. They not only help builders and architects design energy-efficient structures but also address critical issues related to thermal comfort and condensation. As the construction industry increasingly prioritizes energy efficiency and sustainability, the integration of thermal break systems in aluminium profiles is expected to become more widespread, offering a compelling solution for eco-friendly building practices. This innovative technology not only enhances the functionality of the building envelope but also aligns with the global commitment to reduced energy consumption and environmental responsibility.

In contemporary construction, the choice of materials has evolved significantly, leaning towards options that provide durability, aesthetic appeal, and energy efficiency. One often overlooked yet essential component in modern window framing is the aluminum glazing bead. This article delves into the significance of aluminum glazing beads, their benefits, and their role in enhancing window performance.

By replacing them, you breathe new life into your sliding screen door, giving it a refreshed look that complements the overall style of your home By replacing them, you breathe new life into your sliding screen door, giving it a refreshed look that complements the overall style of your home

By replacing them, you breathe new life into your sliding screen door, giving it a refreshed look that complements the overall style of your home By replacing them, you breathe new life into your sliding screen door, giving it a refreshed look that complements the overall style of your home replacement wheels sliding screen door.

replacement wheels sliding screen door.