- The manufacturing process of lithopone involves several steps, including sulfide precipitation, grinding, classification, and packaging. During the sulfide precipitation stage, zinc sulfide and barium sulfate are reacted in an aqueous solution under controlled conditions to form a precipitate of lithopone. The precipitate is then washed, dried, and ground to the desired particle size distribution. Finally, the ground pigment is classified to remove any oversized or undersized particles and packaged for storage and transportation.

- NIOSH research has shown that long-term exposure to high levels of titanium dioxide dust can lead to lung fibrosis, a condition characterized by the scarring of lung tissue. As a result, NIOSH recommends employers implement engineering controls, such as local exhaust ventilation, and administrative measures, like proper personal protective equipment (PPE) and regular medical surveillance, to minimize worker exposure.

In order to achieve the same solids content, the larger filler and the binder should be reduced if necessary.

- The workforce in TIO2 factories embodies a diverse range of skills and expertise, reflecting a microcosm of global collaboration. Engineers, chemists, quality assurance specialists, and logistics coordinators work in harmony, each playing a critical role in the complex manufacturing process. This collective effort underscores the importance of teamwork and knowledge-sharing in driving industrial success.

- One of the primary advantages of using natural titanium dioxide is its eco-friendliness. Unlike synthetic pigments, which are often derived from non-renewable resources and may contain harmful chemicals, natural titanium dioxide is derived from mineral ores and is free from toxic substances. This makes it an ideal choice for companies that are committed to sustainability and reducing their environmental impact.

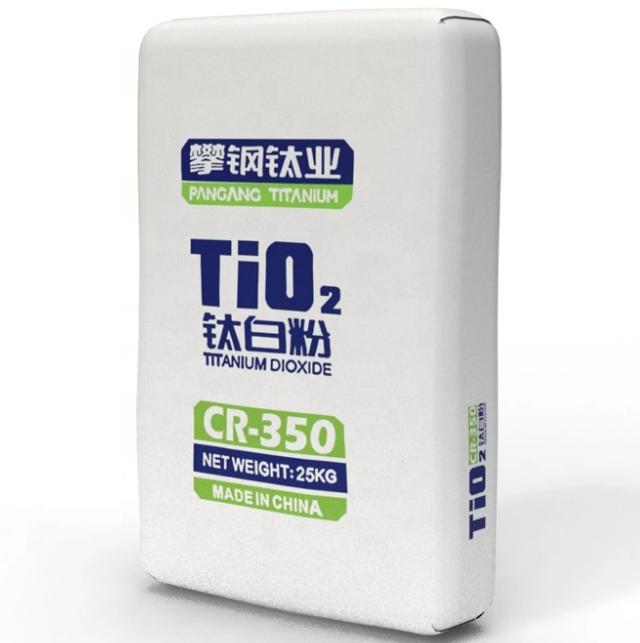

- In the realm of industrial materials, few substances command as much versatility and demand as Titanium Dioxide (TiO2) powder, particularly in its rutile form. This white pigment is not only a cornerstone in the manufacturing of paints, plastics, paper, and sunscreens but also plays a crucial role in photocatalysts and gas sensors. As a leading TiO2 powder rutile manufacturer, our factory epitomizes the confluence of cutting-edge technology and unwavering commitment to quality.

Lithopone B301, Lithopone B311 powder, C.I. Pigment White 5, is a mixture of inorganic compounds, widely utilized as a white pigment. It is composed of a mixture of barium sulfate and zinc sulfide. These insoluble compounds blend well with organic compounds and confer opacity. Lithopone B301, Lithopone B311 powder is famous for the cheap production costs, greater coverage. Related white pigments include titanium dioxide, zinc oxide (zinc white), and zinc sulfide

(1) Konaka et al. 1999. (2) Serpone et al. 2006. (3) Brezova et al. 2004. (4) Dunford et al. 1997. (5) Warner et al. 1997. (6) Salinaro et al. 1997. (7) Maness et al. 1999.

Natural barite and anthracite containing more than 95% barium sulfate are mixed and fed at a ratio of 3:1 (mass). After being crushed to a diameter of less than 2cm, it enters the reduction furnace. The furnace temperature is controlled to be 1000-1200°C in the front section and 500-500 in the back section. 600°C, the reduction furnace rotates at a speed of 80 seconds per revolution, and the reaction conversion rate is 80% to 90%.

It is a national high-tech enterprise, a national top 500 chemical enterprise, and the largest titanium dioxide exporter in China. The main products are TiO2, zirconium products, sulfuric acid and sulfate. Among them, titanium dioxide has reached 120,000 tons, and its export volume has ranked first in the country for three consecutive years. The annual production capacity of the main titanium dioxide is 600,000 tons, ranking first in Asia and fourth in the world.

Lithopone Market

By reducing processed foods in your diet, you can reduce the likelihood of not only eating titanium dioxide but eating other chemicals of concern, Faber said, noting that consumers can also call their elected representatives urging them to support increased food safety legislation and take action with organization alliances like Toxic Free Food FDA. America, once again, is falling behind the rest of the world when it comes to chemical safety.

Although barium sulfate is almost completely inert, zinc sulfide degrades upon exposure to UV light, leading to darkening of the pigment. The severity of this UV reaction is dependent on a combination of two factors; how much zinc sulfide makes up the pigments formulation, and its total accumulated UV exposure. Depending on these factors Lithopone B301, Lithopone B311 powder itself may vary in shade over time, ranging from pure white all the way to grey or even black. To suppress this effect, a dopant might be used, like small amount of cobalt salts, which would be added to the formulation. This process creates cobalt-doped zinc sulfide. The cobalt salts help to stabilize zinc sulfide so it will not have as severe a reaction to UV exposure.

Comparisons

tio2 transparent manufacturer. This trend is being driven by consumer preferences for products that are not only functional but also visually appealing. As a result, manufacturers are increasingly turning to transparent TiO2 as a key ingredient in their formulations to enhance the appearance and performance of their products.

tio2 transparent manufacturer. This trend is being driven by consumer preferences for products that are not only functional but also visually appealing. As a result, manufacturers are increasingly turning to transparent TiO2 as a key ingredient in their formulations to enhance the appearance and performance of their products.North America

Lithopone B301, Lithopone B311 powder is white powder, non-toxic, odorless, insoluble in water, no reaction with H2S and lye, release H2S gas when reacting with strong acids.

anatase titanium dioxide in coatings supplier. We are committed to reducing our environmental impact by implementing eco-friendly practices and using renewable resources whenever possible. Our goal is to provide high-quality products that are environmentally responsible and contribute to a more sustainable future.

Looking ahead to 2023, titanium dioxide will play a key role in various industries. The growth potential of this chemical is huge, and companies like Hebei Caiqing Material Technology Co., Ltd. are well positioned to meet the changing demands of the market. With its individual customization services and dedication to research and development, the company is well-positioned to meet the growing demand and contribute to the advancement of titanium dioxide applications worldwide. Whether in coatings or plastics, titanium dioxide brings innovation, protection and improved product performance to a wide range of customers around the world.