2. Select the Right Fabric Twin needles are perfect for knits, hems, and decorative stitches, but testing on a scrap fabric is always a good idea to ensure your settings yield the desired results.

The Versatility and Advantages of Cylindrical Bed Sewing Machines

- Overall, chain stitch sewing is a versatile and decorative technique that can enhance any sewing or embroidery project. Whether you are a beginner or an experienced crafter, incorporating chain stitch sewing into your work can add an extra element of style and sophistication. So next time you pick up your needle and thread, consider giving chain stitch sewing a try and see where your creativity takes you.

Additionally, the size and design of the throat plate and feed dogs are crucial for sewing leather. A larger throat plate provides more space for maneuvering the material and prevents it from getting caught or stuck during sewing. The feed dogs should also be sturdy and reliable to ensure smooth and even fabric feeding.

When shopping for a four thread overlock machine, be sure to do your research and read reviews from other customers to get an idea of the quality and performance of different models. You can also visit sewing machine stores or online retailers to compare prices and features and find the best deal for your needs.

2. Embroidery Features If embroidery is an essential aspect of your projects, look for machines that come with pre-programmed designs and USB connectivity for custom designs. A larger embroidery area also allows for more complex designs.

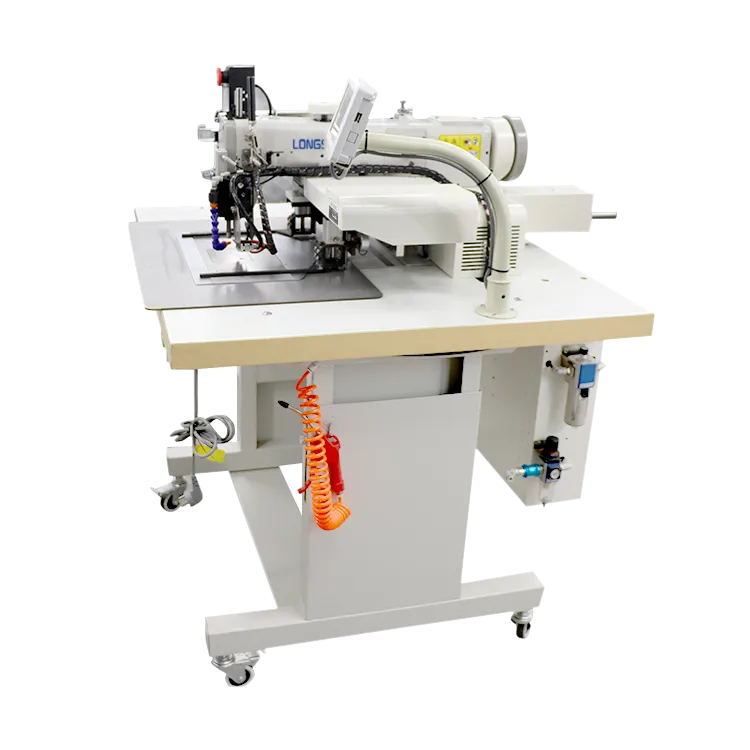

Cylinder arm sewing machines are versatile tools that can significantly enhance the quality and efficiency of your sewing projects. Their unique design makes them ideal for sewing cylindrical or tubular items, and their durability and precision make them suitable for both industrial and personal use. Don’t miss the opportunity to elevate your sewing capabilities—buy a cylinder arm sewing machine today and experience the difference it can make.

In the world of textiles and garment manufacturing, the sewing machine has long been a cornerstone of the industry. Among the various types of sewing machines, the needle feed sewing machine stands out for its ability to enhance efficiency, accuracy, and versatility in fabric handling. This article explores the features, benefits, and applications of needle feed sewing machines, highlighting their significance in modern textile production.

2. Saddle Stitch Machines For those focusing on handcrafted leather jackets, a saddle stitch machine offers precision and control. While these machines may take more time, the craftsmanship they support adds a unique touch to each piece.

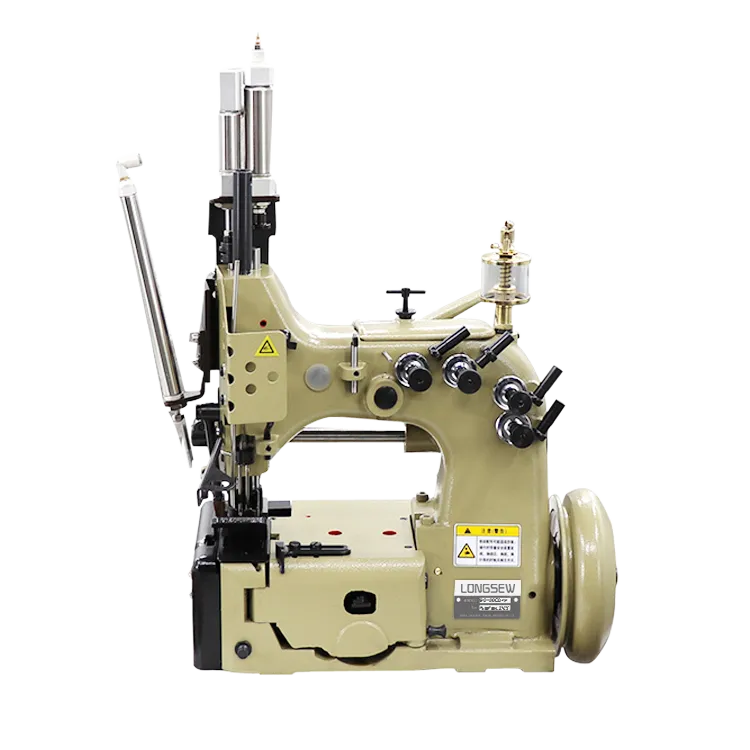

In the realm of textile manufacturing, achieving precision and durability is crucial. One method that has gained recognition in this context is the long arm double needle chain stitch. This technique offers both versatility and efficiency, making it an ideal choice for various fabric applications, from garment construction to home textiles.