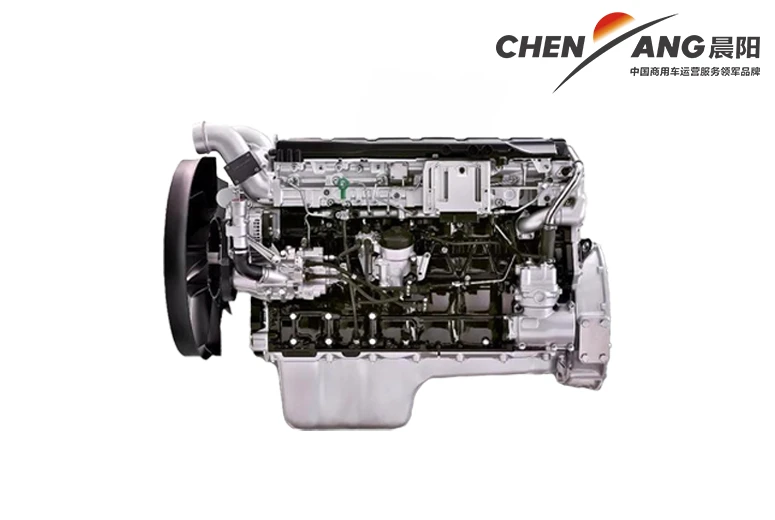

Sinotruk MAN Engine MC13.54-60 | Genuine 540HP Assembly

In the evolving landscape of global logistics and heavy-duty transportation, engine performance, reliability, and efficiency are paramount. The Sinotruk MAN Engine assembly MC13.54-60 stands as a testament to world-class engineering, born from the strategic partnership between Sinotruk and Germany's MAN. This powerhouse is not just a component; it's the beating heart of modern heavy-duty trucks, designed to meet the stringent demands of today's market and the rigorous Euro VI emission standards. This article provides an in-depth exploration of its technical superiority, manufacturing excellence, and real-world applications, establishing it as the definitive choice for businesses seeking unparalleled power and long-term value.

Industry Trends: The Shift Towards High-Power, High-Efficiency Engines

The heavy-duty truck industry is experiencing a significant paradigm shift. Driven by stricter environmental regulations (like Euro VI and China VI), rising fuel costs, and the demand for faster logistics, the market is rapidly moving towards engines that offer higher horsepower and greater torque within an efficient operational window. Data from the "Global Heavy-Duty Truck Market Report" indicates a projected 15% increase in demand for engines above 500 HP over the next five years. This trend underscores the need for advanced powertrain solutions like the Sinotruk MAN Engine assembly MC13.54-60, which perfectly aligns with these market dynamics by delivering robust power without compromising on fuel economy or environmental responsibility.

Unpacking the Powerhouse: Technical Specifications

Understanding the core of the Sinotruk MAN Engine assembly MC13.54-60 begins with its impressive technical specifications. These figures are not just numbers; they represent a finely tuned balance of power, durability, and advanced technology. Each parameter is a result of meticulous German engineering standards, adapted and perfected for global operational conditions.

| Official Technical Parameters: Sinotruk MAN Engine Assembly MC13.54-60 | |

|---|---|

| Engine Model | MC13.54-60 |

| Engine Type | In-line 6-cylinder, 4-stroke, water-cooled, turbocharged with intercooler |

| Displacement | 12.419 Liters |

| Rated Power | 540 HP (397 kW) @ 1900 rpm |

| Maximum Torque | 2500 N·m @ 1050-1350 rpm |

| Emission Standard | Euro VI / China VI |

| Fuel System | Bosch High-Pressure Common Rail System (2000 bar) |

| Aspiration | Turbocharged & Intercooled |

| Bore × Stroke | 126 mm × 166 mm |

| Compression Ratio | 17:1 |

| Minimum Fuel Consumption | ≤186 g/kW·h |

| B10 Life | Over 1.5 million kilometers |

| Net Weight | Approx. 995 kg |

Visualizing Performance: Data-Driven Insights

Data visualization brings the engine's capabilities to life. The following charts illustrate the MC13.54-60's performance metrics in comparison to industry benchmarks and its ideal application scenarios, providing clear, quantifiable proof of its superiority.

Performance Curve: Power & Torque

Competitive Torque Comparison (N·m)

Primary Application Scenarios

Core Technical Advantages: The MAN Technology Edge

The exceptional performance of the Sinotruk MAN Engine assembly MC13.54-60 is not accidental. It is the direct result of integrating proven MAN technology with Sinotruk's manufacturing prowess. Here are the key advantages that set it apart:

1. Unmatched Power and Torque Density

With a peak torque of 2500 N·m available from as low as 1050 rpm, the MC13.54-60 provides exceptional pulling power and acceleration, crucial for heavy haulage and navigating challenging terrains. This wide, flat torque curve means fewer gear shifts, reduced driver fatigue, and improved fuel efficiency. The engine's high power-to-weight ratio ensures that more of the truck's capacity is available for payload.

2. Superior Fuel Economy

Integrating the Bosch high-pressure common rail system with finely-tuned electronic controls allows for precise fuel injection timing and quantity. This, combined with low-friction internal components and an optimized combustion chamber design, results in a minimum fuel consumption rate of ≤186 g/kW·h, a leader in its class. For fleet operators, this translates directly to significant operational cost savings over the vehicle's lifespan.

3. Exceptional Reliability and Durability (B10 Life)

The engine boasts a B10 life of 1.5 million kilometers. The B10 life is an industry-standard metric that indicates the mileage at which 10% of engines are expected to require a major overhaul. This exceptional figure is achieved through the use of high-strength materials like vermicular graphite iron for the cylinder block and head, a robust gear-driven timing system, and rigorous testing that simulates millions of kilometers of real-world use.

4. Advanced Emission Control (Euro VI Compliance)

The MC13.54-60 meets the stringent Euro VI emission standards through an advanced after-treatment system combining EGR (Exhaust Gas Recirculation) + DOC (Diesel Oxidation Catalyst) + DPF (Diesel Particulate Filter) + SCR (Selective Catalytic Reduction) + ASC (Ammonia Slip Catalyst). This sophisticated system not only reduces harmful NOx and particulate matter but does so with minimal impact on engine performance or fuel efficiency, ensuring environmental compliance without compromise.

Manufacturing Excellence: A Transparent Process

The quality of the Sinotruk MAN Engine assembly MC13.54-60 is forged through a state-of-the-art manufacturing process governed by German quality management principles and certified under ISO 9001 and IATF 16949 standards. Each stage is meticulously controlled to ensure every engine meets the highest standards of performance and reliability.

Manufacturing & Quality Assurance Flowchart

1. Raw Material

High-purity vermicular graphite iron for block/head; Forged steel for crankshaft/connecting rods. Certified material analysis.

2. Casting & Forging

Automated casting lines ensure structural integrity. Precision forging creates superior component strength.

3. CNC Machining

German-imported CNC centers machine components to micron-level tolerances, ensuring perfect fit and function.

4. Assembly Line

MAN-standard, digitally monitored assembly line. Smart torque wrenches and robotic arms ensure consistent quality.

5. Hot & Cold Testing

Every engine undergoes rigorous computer-controlled hot and cold testing cycles to verify performance, emissions, and detect any potential leaks or faults.

6. Final Inspection

Final quality audit covering over 300 checkpoints. Conformance to ISO/ANSI standards verified before shipping.

Head-to-Head: Sinotruk MC13 vs. Competitors

To truly appreciate the value of the MC13.54-60, a direct comparison with other leading engines in the market is essential. This table highlights key performance indicators against major competitors.

| Feature | Sinotruk MC13.54-60 | Competitor A (e.g., Cummins ISG) | Competitor B (e.g., Weichai WP13) |

|---|---|---|---|

| Max Power (HP) | 540 HP | ~520 HP | ~550 HP |

| Max Torque (N·m) | 2500 N·m | ~2300 N·m | ~2550 N·m |

| Peak Torque RPM Range | 1050-1350 rpm | 1100-1400 rpm | 1000-1400 rpm |

| B10 Life (km) | 1.5 Million+ km | ~1.2 Million km | ~1.6 Million km |

| Min. Fuel Consumption (g/kW·h) | ≤186 g/kW·h | ~188 g/kW·h | ~185 g/kW·h |

| Core Technology | German MAN License | US-based Design | Domestic with AVL Tech |

Analysis: While competitors may match or slightly exceed certain individual metrics, the Sinotruk MAN Engine assembly MC13.54-60 offers the most compelling overall package. Its strength lies in the perfect balance of a wide and accessible peak torque band, exceptional B10 life derived from MAN's proven engineering, and superior fuel efficiency, making it the most economically viable choice for long-term, heavy-duty operations.

Customized Solutions & Application Versatility

We understand that one size does not fit all. The Sinotruk MAN Engine assembly MC13.54-60 platform is designed for versatility. We offer customized solutions tailored to specific operational needs:

- ECU Remapping: The Engine Control Unit (ECU) can be programmed with different power and torque maps to optimize for fuel economy in long-haul applications or maximize power for heavy construction and mining.

- PTO Integration: Multiple Power Take-Off (PTO) options are available (engine-mounted, flywheel-driven) to power auxiliary equipment like hydraulic pumps in dump trucks or mixers.

- Component Adaptation: Options for different oil pan configurations, alternator capacities, and air compressor models to suit various chassis layouts and power requirements (e.g., for refrigerated transport).

Proven in the Field: Application Cases & Customer Experience

"Switching our long-haul fleet to trucks equipped with the Sinotruk MAN Engine assembly MC13.54-60 was a game-changer. We've seen a consistent 8-10% improvement in fuel economy, and the extended service intervals have significantly reduced our maintenance downtime. The reliability is exactly what you'd expect from MAN-level engineering."

Case Study 1: Long-Haul Logistics

A fleet of 50 tractor units for a major logistics provider was fitted with the MC13.54-60. Over a 12-month period covering 200,000 km per vehicle, the fleet reported an average fuel consumption of 28L/100km under full load, a significant improvement over their previous engine models. The drivers praised the engine's quiet operation and strong engine braking, which enhanced safety and reduced brake wear on long descents.

Case Study 2: Heavy-Duty Construction

In a mining operation in Southeast Asia, dump trucks powered by the MC13.54-60 engine are used to haul ore on steep, unpaved roads. The engine's high torque at low RPMs allows the trucks to easily climb gradients of up to 20% while fully loaded, dramatically improving cycle times. The robust construction has proven resilient against the harsh, dusty environment, with zero engine-related failures reported in the first year of operation.

Ready to Power Your Success?

Experience the unmatched performance and reliability of the Sinotruk MAN Engine. Get a personalized quote and technical consultation for your fleet today.

Explore the MC13.54-60 NowFrequently Asked Questions (FAQ)

The B10 life is a statistical measure of reliability, indicating the operational mileage by which 10% of the engines are projected to require a major overhaul. For the Sinotruk MAN Engine assembly MC13.54-60, a B10 life of 1.5 million kilometers is a testament to its exceptional durability. This is achieved through superior materials like vermicular graphite iron, robust design principles from MAN, and stringent quality control. It means 90% of these engines are expected to operate beyond this milestone without major internal repairs, offering outstanding long-term value and lower total cost of ownership.

The SCR system is a critical component of the engine's after-treatment process. It works by injecting a liquid-reductant agent, typically automotive-grade urea (AdBlue), into the exhaust stream. As the exhaust gases pass through the SCR catalyst, the AdBlue reacts with the harmful Nitrogen Oxides (NOx), converting them into harmless nitrogen, water, and a small amount of carbon dioxide. This process is highly effective, reducing NOx emissions by up to 90% and allowing the MC13.54-60 to comfortably meet the stringent Euro VI emission regulations.

Vermicular Graphite Iron (VGI), also known as Compacted Graphite Iron (CGI), offers a superior combination of properties compared to traditional gray iron. It possesses higher tensile strength and fatigue resistance, allowing for a lighter yet stronger engine block design. This contributes to the engine's excellent power-to-weight ratio. Furthermore, VGI has better thermal conductivity and damping characteristics, which leads to more efficient heat dissipation, reduced engine vibration, and quieter operation—all key attributes of the premium feel and performance of the MC13.54-60.

Yes, the Bosch ECU on the Sinotruk MAN Engine assembly MC13.54-60 is highly adaptable. We offer authorized ECU remapping services to optimize engine performance for specific needs. For example, a "fuel economy map" can be applied for long-haul trucking to maximize mileage, while a "power map" can unlock more aggressive performance for heavy-haulage or construction tasks. We can also adjust parameters to better suit regional variations in diesel fuel quality, ensuring optimal performance and longevity worldwide.

Thanks to its MAN technology foundation, the MC13.54-60 features extended service intervals, reducing downtime and maintenance costs. A typical maintenance schedule under standard operating conditions is:

- Engine Oil & Filter Change: Up to 100,000 kilometers (depending on oil quality and operational load).

- Fuel Filter Replacement: Every 60,000 to 80,000 kilometers.

- Valve Clearance Adjustment: Not required for the first 500,000 kilometers due to the robust valvetrain design.

The Bosch high-pressure common rail system (up to 2000 bar) atomizes fuel into an extremely fine mist, enabling more complete and efficient combustion. This has several key benefits:

- Improved Fuel Efficiency: More energy is extracted from every drop of fuel, lowering consumption.

- Higher Power & Torque: Efficient combustion translates directly into better engine output.

- Lower Emissions: More complete burning of fuel reduces the formation of particulate matter (soot).

- Quieter Operation: It eliminates the classic "diesel knock" by allowing for multiple small injections per combustion cycle, smoothing out the pressure rise in the cylinder.

The Sinotruk MAN Engine assembly MC13.54-60 is designed with dimensions and mounting points that are standard for its class, making it a direct fit for Sinotruk's SITRAK and HOWO series trucks. For retrofitting into other chassis, its footprint is comparable to other 12-13L class engines. Potential modifications could include adjustments to engine mounts, cooling system connections (radiator and intercooler piping), exhaust routing for the after-treatment system, and integration with the vehicle's CAN bus system. We provide detailed installation manuals and technical support to ensure a smooth integration process.

References & Further Reading

- SAE International. (2021). Advanced Diesel Engine and Fuel Injection Technologies. SAE Technical Paper Series. https://www.sae.org/publications/technical-papers

- MAN Truck & Bus. (2023). Engine Technology for Commercial Vehicles. MAN SE Official Publication. https://www.mantruckandbus.com/en/company/technology-and-innovation.html

- FleetOwner Magazine. (2022). "The Rise of High-Efficiency Powertrains in Heavy-Duty Trucking." https://www.fleetowner.com

-

2BFY Traction Series Grain Fertilizer Seeder-Chenyang Group|Seeding & Fertilizing Integration&High EfficiencyNewsAug.06,2025

-

2BFY Traction Series Grain Fertilizer Seeder - Chenyang Group | Integrated Seeding and FertilizingNewsAug.06,2025

-

2BFY Traction Series Grain Fertilizer Seeder-Chenyang Group|Integrated Seeding&Fertilizing,Durable Agricultural MachineryNewsAug.05,2025

-

2BFY Traction Series Grain Fertilizer Seeder-Chenyang Group|Integrated Seeding&Versatile Crop AdaptabilityNewsAug.05,2025

-

Grain Fertilizer Seeder-2BFY Traction Series|Precision Farming,Integrated SeedingNewsAug.05,2025

Popular products