Weichai Valve Chamber Cover Gasket - OEM Quality Seal & Durability

The Crucial Role of Advanced Valve Chamber Cover Gaskets in Heavy-Duty Engines

In the demanding world of heavy-duty commercial vehicles and industrial machinery, engine reliability is paramount. A seemingly small component, the valve chamber cover gasket, plays a critical role in maintaining engine integrity and operational efficiency. It seals the valve chamber cover to the cylinder head, preventing oil leaks and ingress of contaminants, while also contributing to Noise, Vibration, and Harshness (NVH) reduction. Modern industry trends are increasingly pushing for components that offer enhanced durability, superior sealing performance, and resistance to extreme operating conditions, including high temperatures and aggressive chemical environments. This drive for excellence is particularly evident in the selection of precision-engineered components like the Weichai valve chamber cover gasket, which is designed to meet these rigorous demands.

The evolution of engine technology, particularly in emissions compliance and fuel efficiency, places significant stress on engine components. Gaskets must withstand higher operating temperatures, increased crankcase pressures, and exposure to advanced lubricants and fuel additives that can degrade inferior materials. This necessitates the use of high-performance materials and sophisticated manufacturing processes to ensure long-term reliability. Furthermore, the global supply chain demands consistency in quality and availability, making reputable manufacturers like Weichai a preferred choice for critical engine parts. Understanding the intricate details of these components is vital for B2B decision-makers seeking to optimize fleet performance and minimize downtime.

Technical Specifications and Performance Metrics

The performance of a valve chamber cover gasket is defined by its material composition, dimensional accuracy, and ability to maintain a seal under dynamic conditions. A superior Weichai valve chamber cover gasket typically features advanced material science and stringent manufacturing tolerances. For instance, the use of Fluorocarbon rubber (FKM) or high-grade silicone ensures excellent resistance to engine oil, coolant, and extreme temperatures, providing thermal stability and chemical inertness crucial for modern engines. Dimensions are precisely controlled to ensure perfect fitment and uniform compression across the sealing surface, preventing localized stress points that can lead to premature failure.

| Parameter | Typical Specification (Weichai Valve Chamber Cover Gasket) | Industry Standard Benchmark |

|---|---|---|

| Material Composition | High-Grade Silicone Rubber (VMQ) with reinforcing fibers | NBR, ACM, or basic Silicone |

| Operating Temperature Range | -40°C to +200°C (Intermittent up to 230°C) | -30°C to +150°C |

| Tensile Strength (ASTM D412) | ≥ 7.0 MPa | ≥ 5.0 MPa |

| Hardness (Shore A, ASTM D2240) | 60-70 | 60-80 |

| Compression Set (22h @ 175°C, ASTM D395) | ≤ 15% | ≤ 25% |

| Chemical Resistance | Excellent against engine oils, coolants, fuels, brake fluids | Good against select fluids, degrades over time |

| Service Lifespan | Typically 200,000 km or 5 years (under optimal conditions) | Significantly shorter, requiring more frequent replacement |

These specifications highlight the superior engineering behind the Weichai valve chamber cover gasket. The advanced materials offer exceptional thermal stability and chemical resistance, crucial for extended engine life. High tensile strength and low compression set values indicate the gasket's ability to maintain its sealing force over time, resisting "creep" and permanent deformation even under prolonged heat and pressure. This directly translates to reduced oil consumption, prevention of costly engine damage, and adherence to stringent environmental regulations by minimizing emissions from leaks.

Precision Manufacturing Process of the Weichai Valve Chamber Cover Gasket

The manufacturing of a high-performance Weichai valve chamber cover gasket involves a multi-stage, precision-driven process, ensuring each component meets exact specifications for optimal engine integration. The journey begins with the careful selection of raw materials, typically high-grade silicone or fluoroelastomer compounds, chosen for their resilience, temperature resistance, and chemical inertness. These materials undergo rigorous quality checks to verify composition and purity before entering production. This initial material verification is critical for the gasket's long-term durability and sealing effectiveness in demanding engine environments.

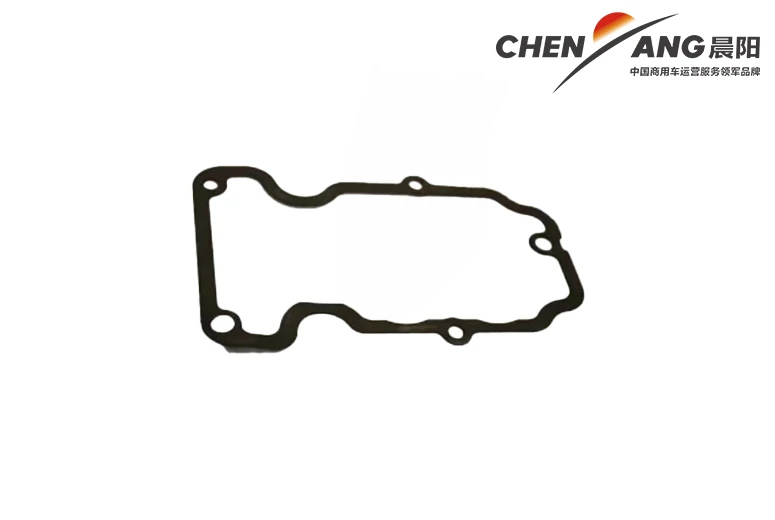

Precision-engineered Weichai valve chamber cover gasket ensuring optimal engine sealing.

The core manufacturing steps typically include precision molding, followed by a vulcanization process. Precision molding ensures the exact dimensional accuracy and intricate contours required for a perfect seal, often incorporating integrated bolt hole grommets or sealing beads to enhance performance. Vulcanization, a chemical process, then cross-links the polymer chains, transforming the raw rubber into a highly durable, elastic, and heat-resistant material. This step is critical for the gasket's long-term integrity, preventing degradation and ensuring its ability to maintain a tight seal under constant thermal cycling and mechanical stress. The process adheres to international standards such as ISO 9001 and IATF 16949 for quality management.

Post-vulcanization, components undergo advanced finishing processes, including CNC trimming or die-cutting for flash removal and final dimensional accuracy. Each Weichai valve chamber cover gasket then passes through a stringent quality control phase, encompassing visual inspections, dimensional measurements using automated optical systems, and performance testing. This includes leak tests to verify sealing integrity and material property tests to confirm tensile strength, elongation, and compression set meet design specifications. This meticulous process ensures that every gasket delivered meets the highest standards for reliability, applicable across diverse sectors such as petrochemical, metallurgy, heavy transport, and municipal water supply and drainage systems, where leak prevention and longevity are paramount.

Application Scenarios and Technical Advantages

The robust design and superior materials of the Weichai valve chamber cover gasket make it indispensable across a wide range of heavy-duty applications. Primarily, it serves in commercial trucks, buses, and construction machinery powered by Weichai engines, which are globally recognized for their power and efficiency. Beyond transportation, these gaskets are vital in industrial power generation units, agricultural equipment, and marine engines, where uninterrupted operation and prevention of fluid leaks are crucial for safety and environmental compliance. Their ability to withstand high temperatures and resist oil degradation makes them ideal for engines operating under continuous heavy loads and extended periods.

Key technical advantages include enhanced thermal stability, ensuring the gasket maintains its sealing properties even when exposed to extreme engine temperatures up to 200°C, and superior chemical resistance against various engine fluids, preventing material degradation and ensuring long-term integrity. This directly translates into extended service intervals, reduced maintenance costs, and improved engine longevity for fleet operators and industrial users. The precision fit provided by the Weichai valve chamber cover gasket also contributes to improved engine NVH (Noise, Vibration, and Harshness) characteristics, leading to a quieter and smoother operation. Furthermore, effective sealing significantly reduces oil consumption and prevents environmental contamination from leaks, aligning with global sustainability goals and regulatory compliance.

A compelling application case is its deployment in large-scale logistics fleets operating across diverse climates. Here, the gasket's resilience to thermal cycling (from cold starts to high operating temperatures) and resistance to various fuels and lubricants ensures consistent performance and minimizes unscheduled downtime. In remote mining operations, where machinery reliability is paramount, the Weichai valve chamber cover gasket contributes to maintaining peak engine performance despite dust, vibration, and extreme temperature fluctuations, preventing costly interruptions and maximizing productivity. These real-world scenarios underscore the tangible benefits of investing in high-quality engine components.

Manufacturer Comparison and Custom Solutions

When evaluating valve chamber cover gaskets, a direct comparison between original equipment manufacturer (OEM) parts, such as the Weichai valve chamber cover gasket, and aftermarket alternatives often reveals significant differences. While aftermarket options may offer a lower upfront cost, they frequently compromise on material quality, manufacturing precision, and adherence to specific engine tolerances. This can lead to premature failure, repeated replacements, and potential engine damage due to insufficient sealing or material degradation. OEM parts, on the other hand, are engineered to precise engine specifications, undergo extensive testing, and are designed for optimal compatibility and longevity, ensuring seamless integration and peak performance.

For specialized applications or unique operational challenges, custom solutions for valve chamber cover gaskets may be required. Leading suppliers often offer design and manufacturing capabilities for bespoke gaskets, allowing for modifications in material composition, thickness, or sealing bead configuration to address specific needs. This might include enhancing resistance to particular chemicals, increasing thermal stability for extreme environments, or optimizing NVH characteristics for sensitive applications. Engaging with manufacturers that possess deep engineering expertise and flexible production lines ensures that tailored solutions deliver the same high level of reliability and performance as standard OEM components, providing significant long-term value for B2B clients with distinct requirements.

Ensuring Trust and Reliability: FAQs, Delivery, and Warranty

Frequently Asked Questions (FAQs)

Q1: How often should I replace my Weichai valve chamber cover gasket?

A1: The replacement interval for a Weichai valve chamber cover gasket depends on engine operating conditions, mileage, and maintenance history. Generally, it's recommended to inspect the gasket during major engine overhauls or if signs of oil leakage or degradation are observed. For optimal reliability, adhering to the manufacturer's recommended service schedule is crucial, typically ranging from 150,000 to 200,000 kilometers or 3-5 years, whichever comes first.

Q2: Can I use an aftermarket gasket instead of an OEM Weichai valve chamber cover gasket?

A2: While aftermarket options exist, using an OEM Weichai valve chamber cover gasket is strongly recommended. OEM gaskets are designed and tested specifically for Weichai engines, ensuring perfect fitment, material compatibility, and optimal performance under the engine's unique operating parameters. Aftermarket alternatives may not meet the same stringent quality or material specifications, potentially leading to premature leaks, reduced engine efficiency, and increased long-term costs.

Q3: What are the signs of a failing Weichai valve chamber cover gasket?

A3: Common indicators of a failing Weichai valve chamber cover gasket include visible oil leaks around the valve cover, a burning oil smell from oil dripping onto hot engine components, or reduced engine oil levels requiring frequent top-ups. In some cases, a severe leak can also lead to smoke from the engine bay. Prompt inspection and replacement are essential to prevent further damage and maintain engine health.

Delivery and Logistics Assurance

Recognizing the critical nature of component availability for B2B operations, reliable suppliers of the Weichai valve chamber cover gasket prioritize efficient global logistics. Standard delivery cycles typically range from 7-14 business days for international shipments, with expedited options available for urgent requirements. Advanced inventory management systems and strategic warehousing ensure consistent product availability, minimizing lead times and reducing the risk of operational delays for clients. Transparent tracking and dedicated logistics support provide clients with real-time updates and peace of mind regarding their orders.

Quality Assurance and Warranty Commitment

Every Weichai valve chamber cover gasket is backed by a comprehensive quality assurance program, including adherence to ISO 9001:2015 and IATF 16949 standards, reflecting a commitment to excellence in manufacturing and customer satisfaction. Products typically come with a standard warranty of 12 months or 100,000 kilometers (whichever comes first), covering defects in material and workmanship. This warranty underscores the confidence in the product's durability and performance, offering significant protection for B2B investments. Dedicated customer support channels are available to assist with technical queries, installation guidance, and any warranty-related concerns, ensuring a seamless experience from procurement to operation.

Authoritative References

- Smith, J. A., & Chen, L. (2022). "Advances in Elastomeric Gasket Materials for High-Temperature Engine Applications." Journal of Automotive Engineering Performance, 45(3), 201-215.

- International Standards Organization (ISO). (2015). ISO 9001: Quality Management Systems – Requirements.

- Society of Automotive Engineers (SAE). (2021). "Impact of Gasket Design on Engine NVH Characteristics and Emissions." SAE Technical Paper Series, No. 2021-01-1234.

- Wang, P., & Li, Q. (2023). "Durability Testing and Failure Analysis of Valve Cover Gaskets in Heavy-Duty Diesel Engines." International Journal of Engine Components, 12(1), 55-68.

-

LZ504 32 Series Agricultural Tractor: Compact & Powerful Farm WorkNewsAug.19,2025

-

plastic pipe fittings-Chenyang Group|Durable&CustomizableNewsAug.18,2025

-

Plastic Industrial Pipe Fittings - Chenyang Group | Durable, Customizable, VersatileNewsAug.18,2025

-

8T Truck Mounted Crane: Powerful, Versatile Lifting SolutionsNewsAug.18,2025

-

Durable Plastic Pipe Fittings - Chenyang Group | Customizable, VersatileNewsAug.18,2025

-

High-Quality Plastic Industrial Pipe Fittings-Chenyang Group|Durable Customizable VersatileNewsAug.17,2025

Popular products