wheel loader material

Understanding Wheel Loader Materials

Wheel loaders are essential machinery in various industries, especially in construction, agriculture, and mining. These versatile machines are primarily designed to move and load materials such as soil, gravel, sand, and other aggregates. Given their critical role in heavy-duty applications, the choice of materials used in manufacturing wheel loaders is paramount to ensure durability, performance, and efficiency.

Key Materials Used in Wheel Loader Construction

1. Structural Steel The primary material used in the frame and body of wheel loaders is structural steel. Steel provides the necessary strength and durability to withstand the significant stresses encountered during operation. High-tensile steel is often utilized for its excellent strength-to-weight ratio, making it ideal for heavy machinery. It enables manufacturers to create lighter machines without compromising structural integrity.

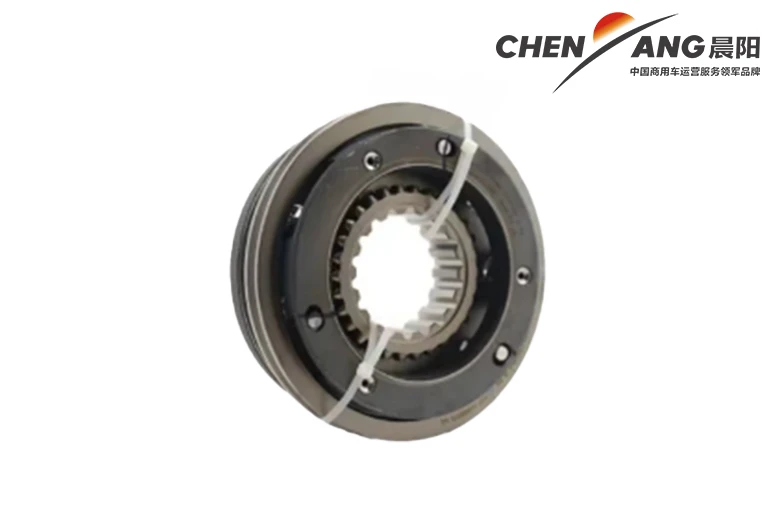

2. Cast Iron For components that require high toughness and resistance to wear, cast iron is frequently employed. Parts such as engine blocks, transmission housings, and counterweights benefit from cast iron's durability and ability to absorb vibrations. Its ability to withstand high temperatures and resist corrosion makes it an excellent choice for critical engine components.

3. Aluminum Alloys In recent years, there has been a growing trend towards using aluminum alloys in various wheel loader components, especially in smaller models. Aluminum is significantly lighter than steel, which allows for greater fuel efficiency and maneuverability. Components such as wheels, hydraulic reservoirs, and enclosures may be made from aluminum or aluminum alloys to reduce the overall weight of the loader while maintaining strength.

4. Rubber and Composite Materials Tires are undoubtedly one of the most critical components of wheel loaders. The choice of rubber and composite materials in tire manufacturing can greatly impact the machine's performance on different terrains. High-quality rubber compounds are essential for ensuring good traction, durability, and resistance to wear. Additionally, composite materials are utilized in certain applications to enhance resistance to chemical exposure and extreme temperatures.

wheel loader material

5. Hydraulic System Components The hydraulic system is the heart of a wheel loader, allowing for the smooth operation of various functions, including lifting and tilting the bucket. Hydraulic cylinders, hoses, and fittings are often made from high-grade steel and rubber to withstand high pressures and resist wear and corrosion. The use of advanced materials in hydraulic systems contributes to the overall efficiency and reliability of the machine.

The Importance of Material Selection

The selection of materials for wheel loaders directly impacts their performance, lifespan, and maintenance needs. Proper material choice ensures that machines can operate effectively in harsh environments while minimizing the risk of breakdowns. For example, using high-quality steel in critical load-bearing components can reduce wear and extend the life of the machine, ultimately saving costs related to repairs and downtime.

Moreover, innovation in material science has led to the development of advanced coatings and treatments that enhance the performance of traditional materials. Rust-resistant coatings, for instance, can extend the longevity of steel components, while heat-resistant treatments can improve the performance of engine parts. As manufacturers continue to explore new materials, the future of wheel loader design promises even greater efficiency and durability.

Conclusion

In conclusion, the choice of materials in the construction of wheel loaders is crucial for their efficiency, performance, and longevity. From structural steel providing strength to lightweight aluminum enhancing fuel efficiency, each material plays a significant role in the machine's operation. As technology advances, the exploration of new materials and innovations will likely lead to the development of even more robust and efficient wheel loaders, further underscoring their importance across various industries. Understanding the materials used in wheel loaders is essential for stakeholders who aim to maximize productivity and minimize costs in their operations.

-

SINOTRUK HOWO 84 Electric Dump Truck for Eco-Friendly Heavy HaulingNewsJul.26,2025

-

The Fast 16-Gear Manual Transmission Assembly for Heavy TrucksNewsJul.25,2025

-

Mercedes Benz Actros 1848 42 Tractor Truck for Sale - Reliable PerformanceNewsJul.24,2025

-

High-Quality Water Pump Assembly for Sinotruk Trucks – Durable & ReliableNewsJul.23,2025

-

Premium Truck Engine Antifreeze Coolant Fluid for Heavy Duty VehiclesNewsJul.22,2025

-

FOTON View G7 Mini Bus: Affordable & Spacious TransportNewsJul.22,2025

Popular products